highlights

• virtually vibration-free

• small size

• no mechanical moving parts

• only the sample area is cryogenically cooled

• no liquid nitrogen

no compressor needed.

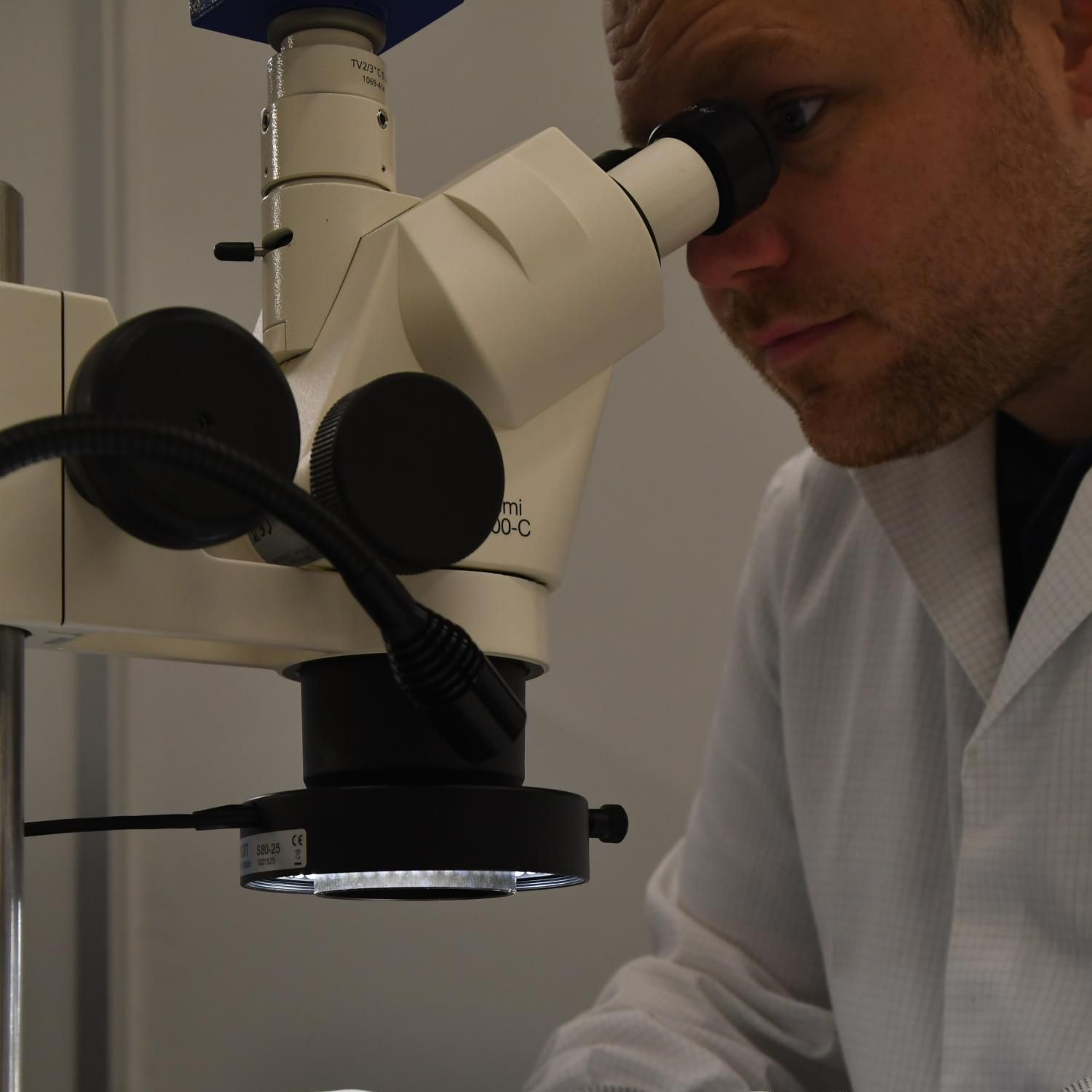

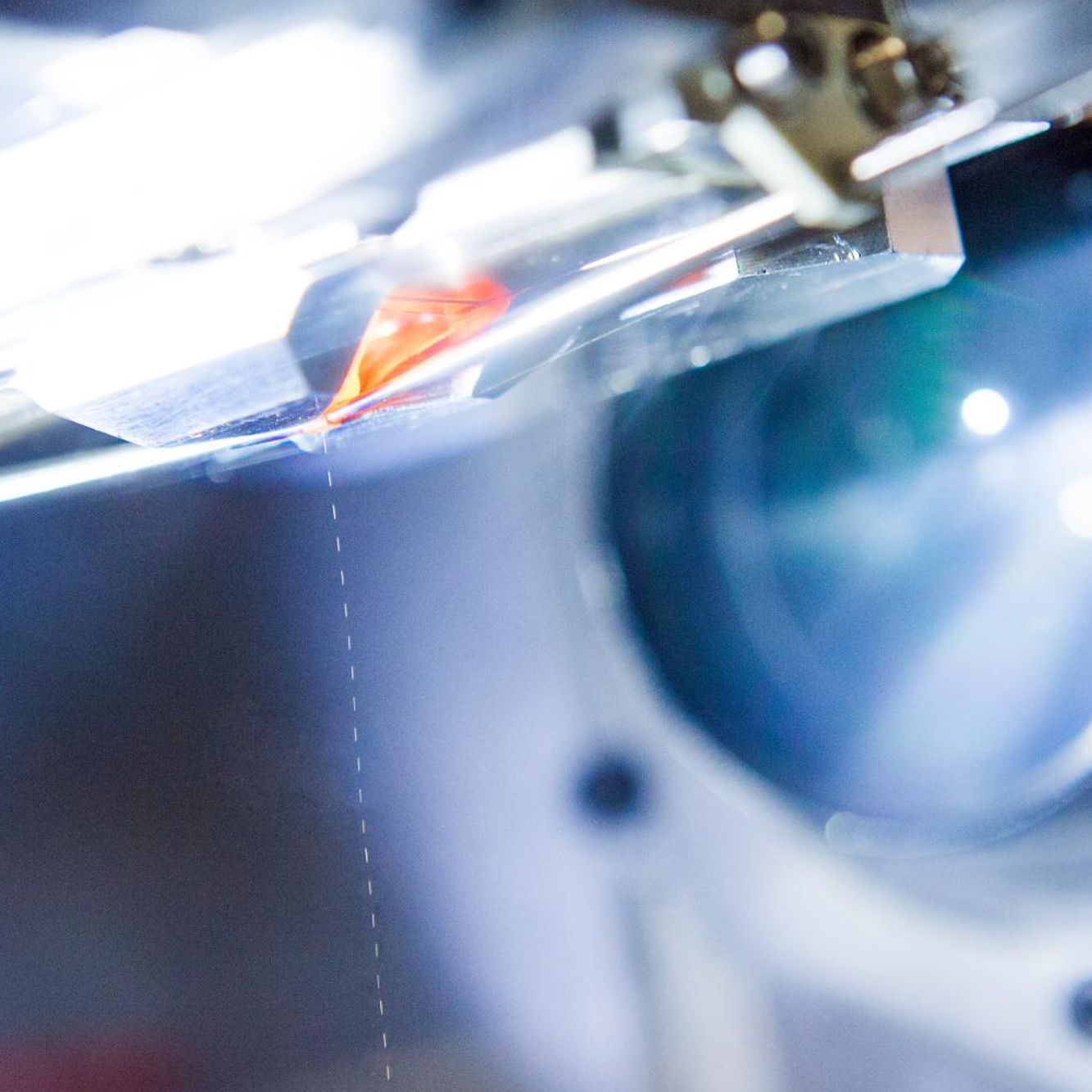

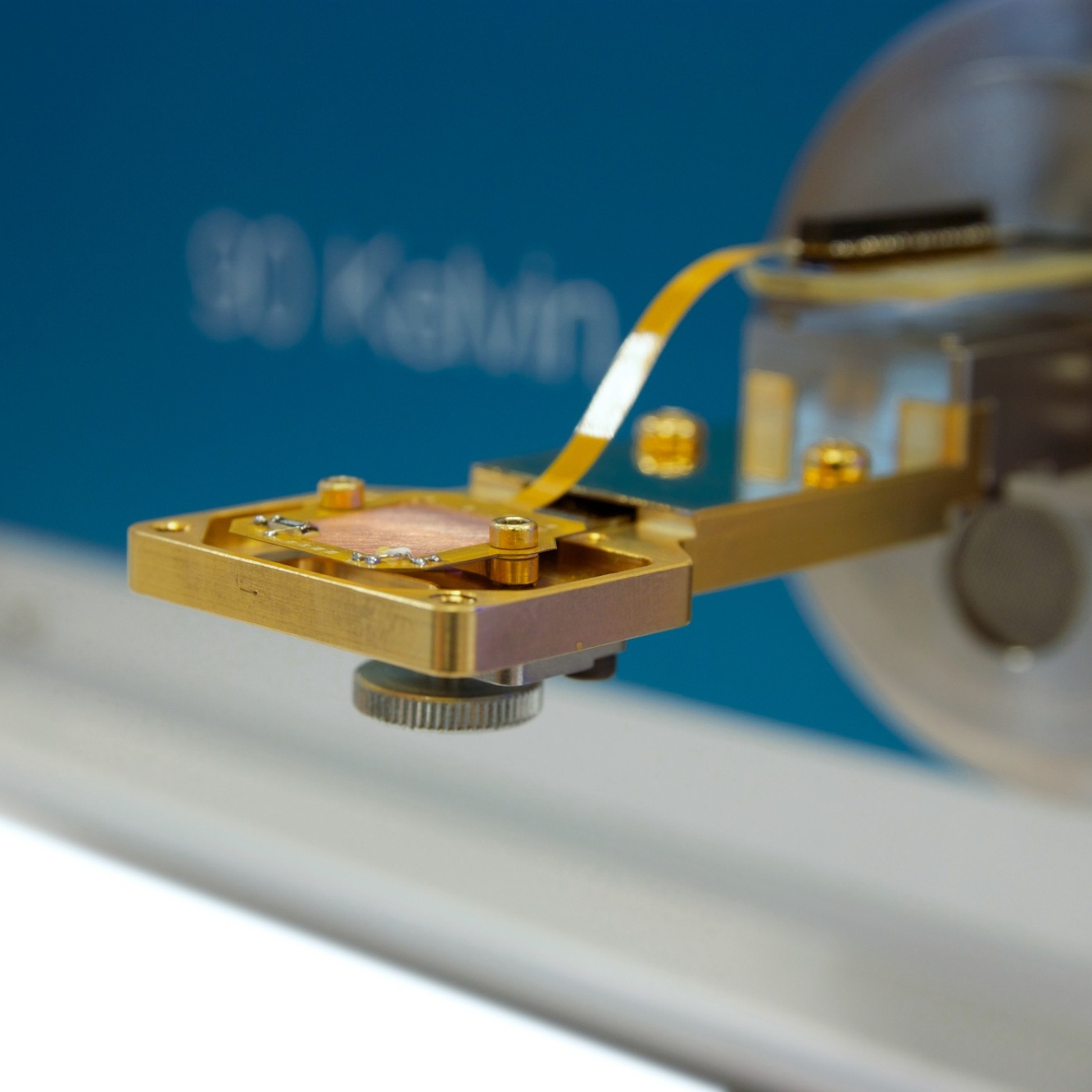

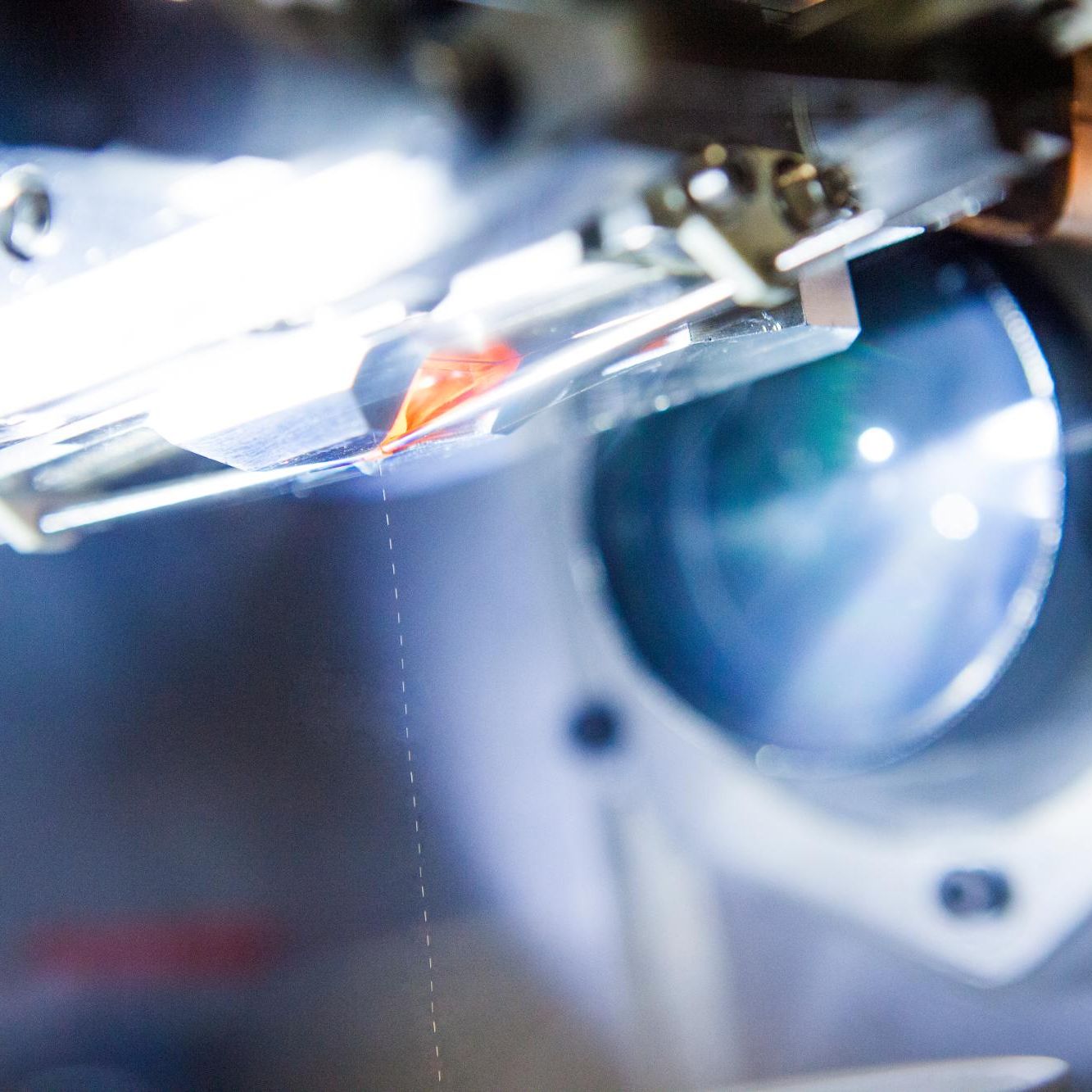

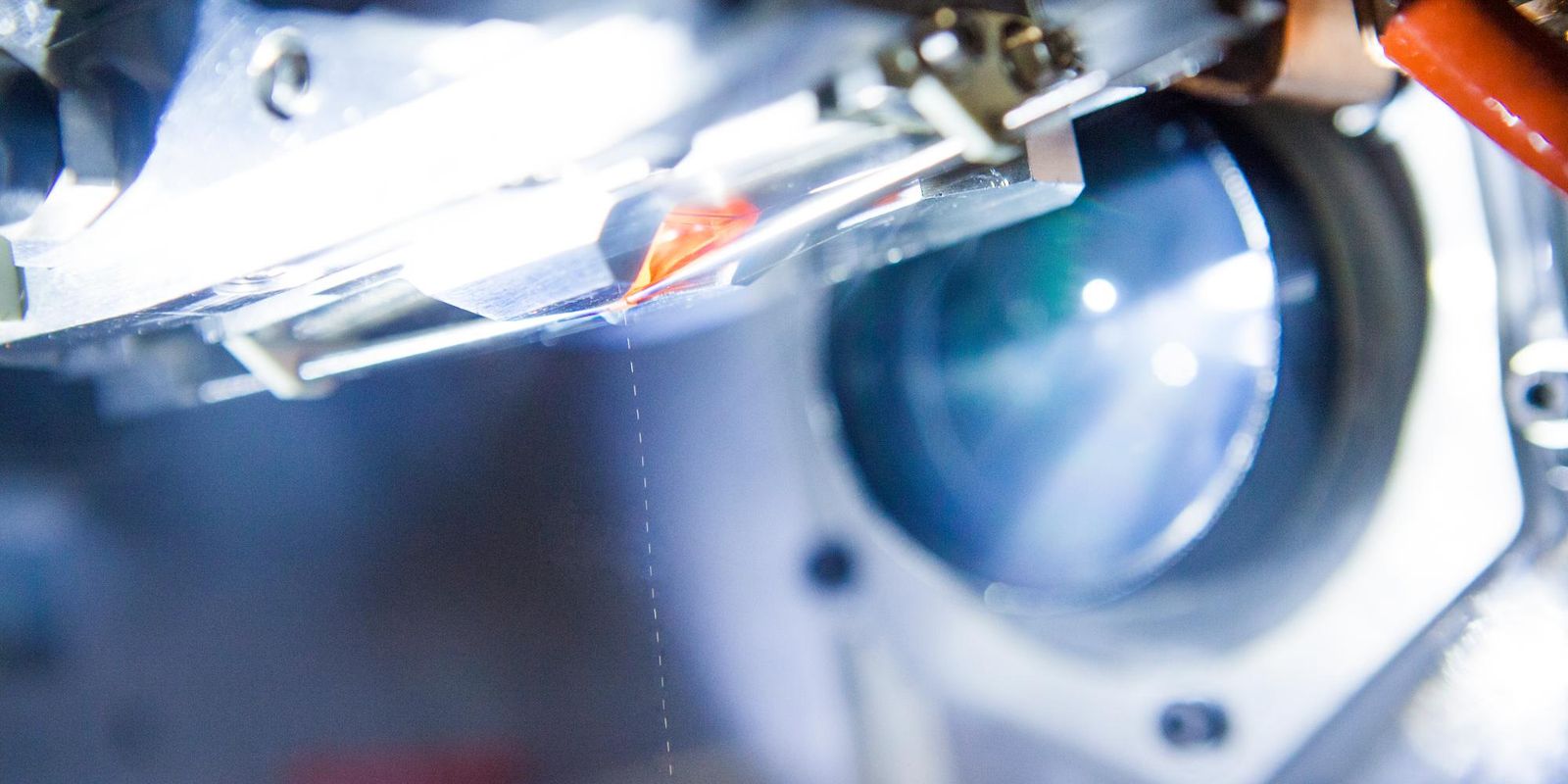

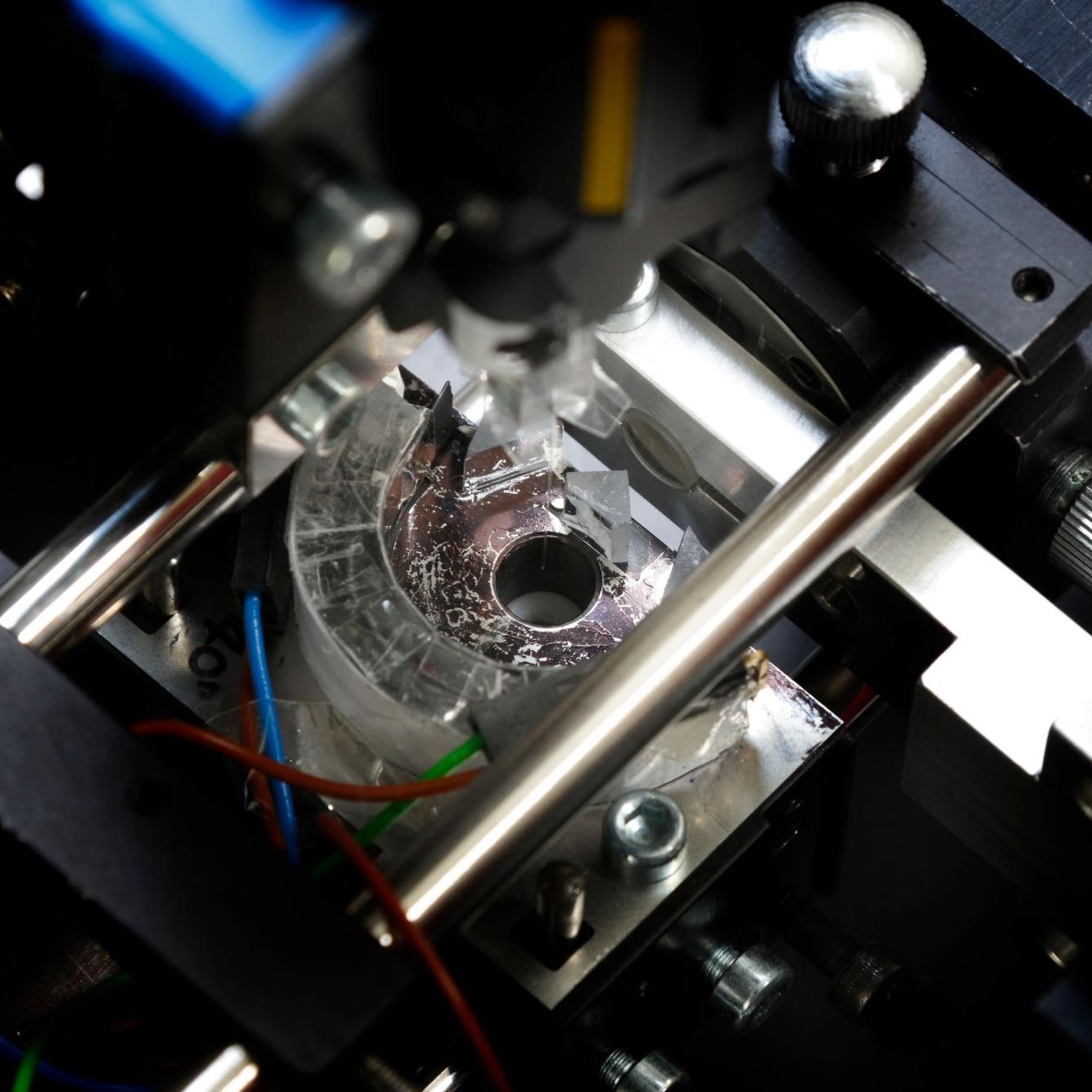

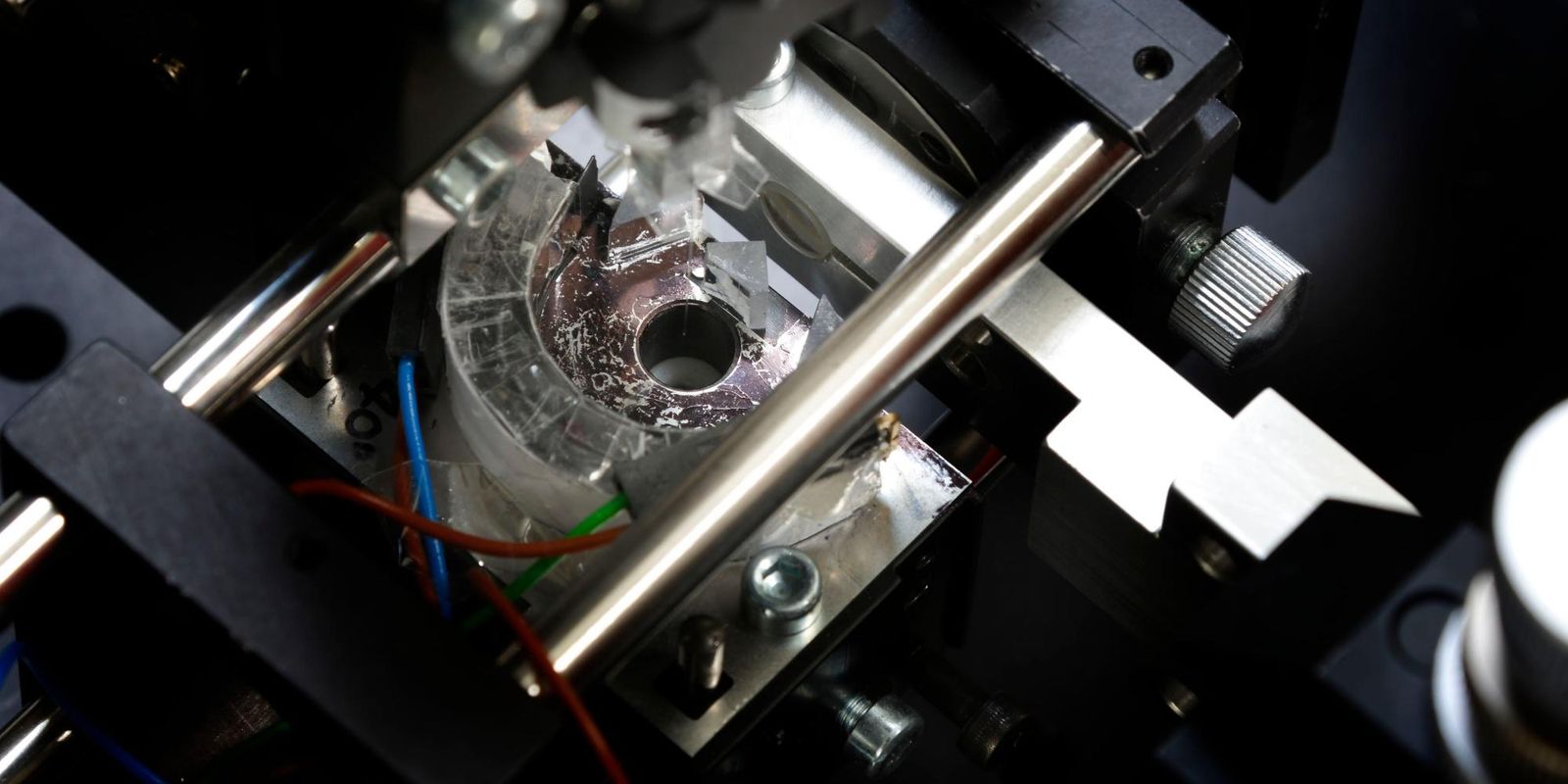

16 centimeters – that is all. It suffices to keep cryogenic samples at temperatures between minus 150 to almost minus 200 degrees Celsius. This size allows for easy integration in an electron microscope setup. Various types of sample holders can be connected to a tube the size of a little finger, which houses the cooler: a micro-fluidic chip made with lithography techniques. A small box fixed to the tube contains some tubing and enables mounting: no mechanical parts are involved. This means hardly any vibrations – vital for electron microscopy. The Kryoz cold-stage can be combined with a stage offering six degrees of freedom, enabling sample study from any angle.

The ‘secret’ of the cooler chip is that it allows for an expansion cycle of nitrogen gas through the chips’ channels without a compressor. A very important benefit is the temperature gradient over a tiny distance – from room temperature to almost minus 200 over mere centimeters. Only the sample area is cold, all surrounding hardware stays at environmental temperature.

The Kryoz cold-stage is operated with normal nitrogen bottles. The tiny flow makes the system frugal with gas. During non-stop operation, a bottle will last for a whole week.

rock solid stability.

The Kryoz cold-stage at present typically creates 1 nanometer peak to peak vibrations. Demcon now aims at an even better performance: engineers work at reaching 0.1 nm p2p or lower. Almost equally important is thermal drift. Temperature control is the key to stability here. The Kryoz cold-stage has an accuracy better than 10 milliKelvin stabilized temperature control between 100 to 300 degrees Kelvin, retaining drift below 3 nanometer per minute.

The Kryoz cold-stage is already integrated in the Delmic Cryo FIB/SEM. The field of application is now extended to X-Ray Microscopy (XRM), Transmission Electron Microscopy (TEM) and Laser Scanning Microscopy (LSM).

“if anything is slightly off with one of the dozens of components, the end product will not work.”

The Kryoz is an extremely complicated piece of equipment. If anything is slightly off with one of the dozens of components, or the procedure is not properly followed, the end product will not work. That would make reverse engineering quite a challenge. To anyone who would like to try, I would say: good luck.

explore more cases.

more cases & tech insights.

Hot head on a cool stage

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

Hemics HandScan: fast, painless and objective screening for rheumatoid arthritis

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more