highlights

• sub-nanometer positioning resolution

• actuation in six degrees of freedom

• magnetic shielding down to tens of nanoTesla

• complexly shaped and tightly toleranced cylinder

metrology and magnetic shielding.

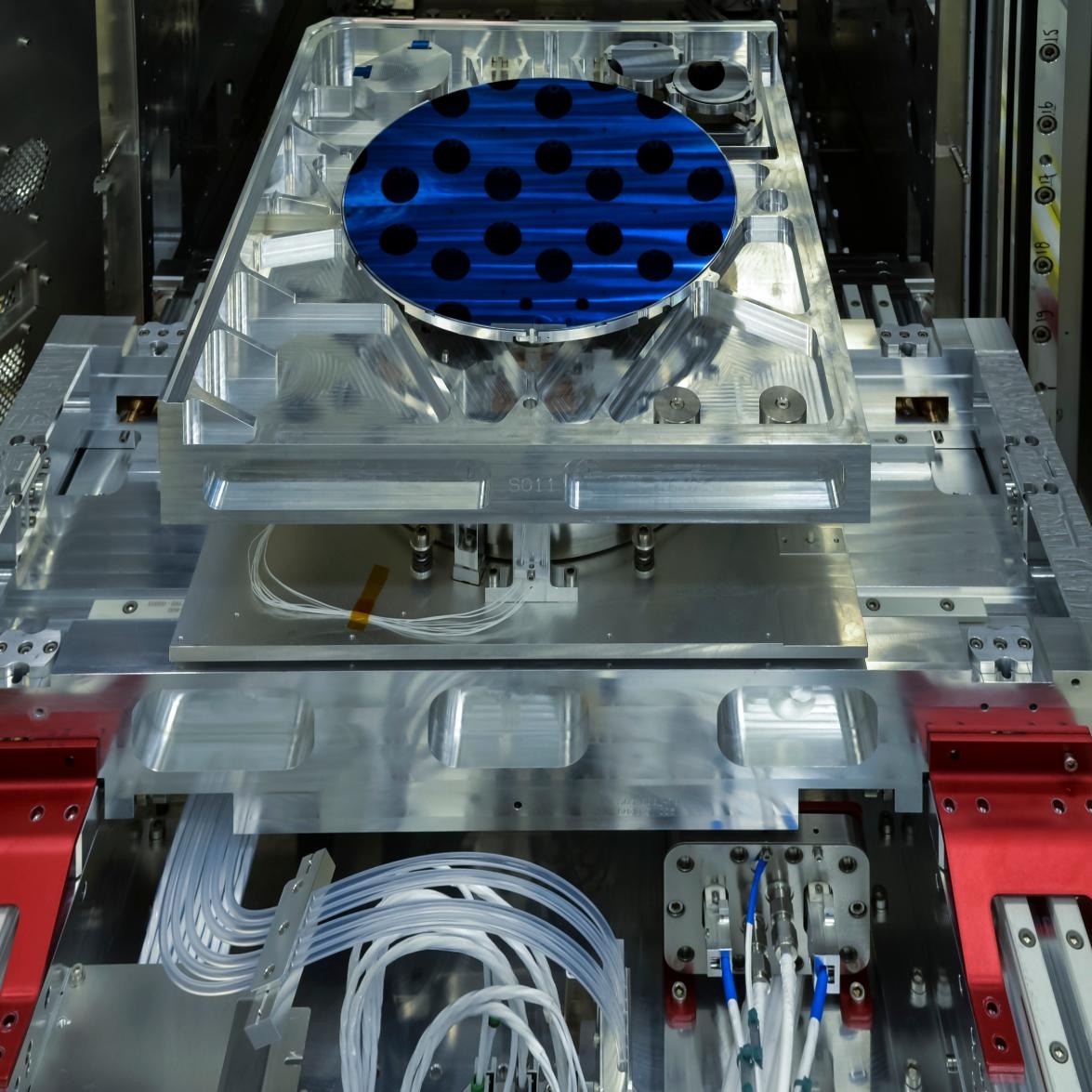

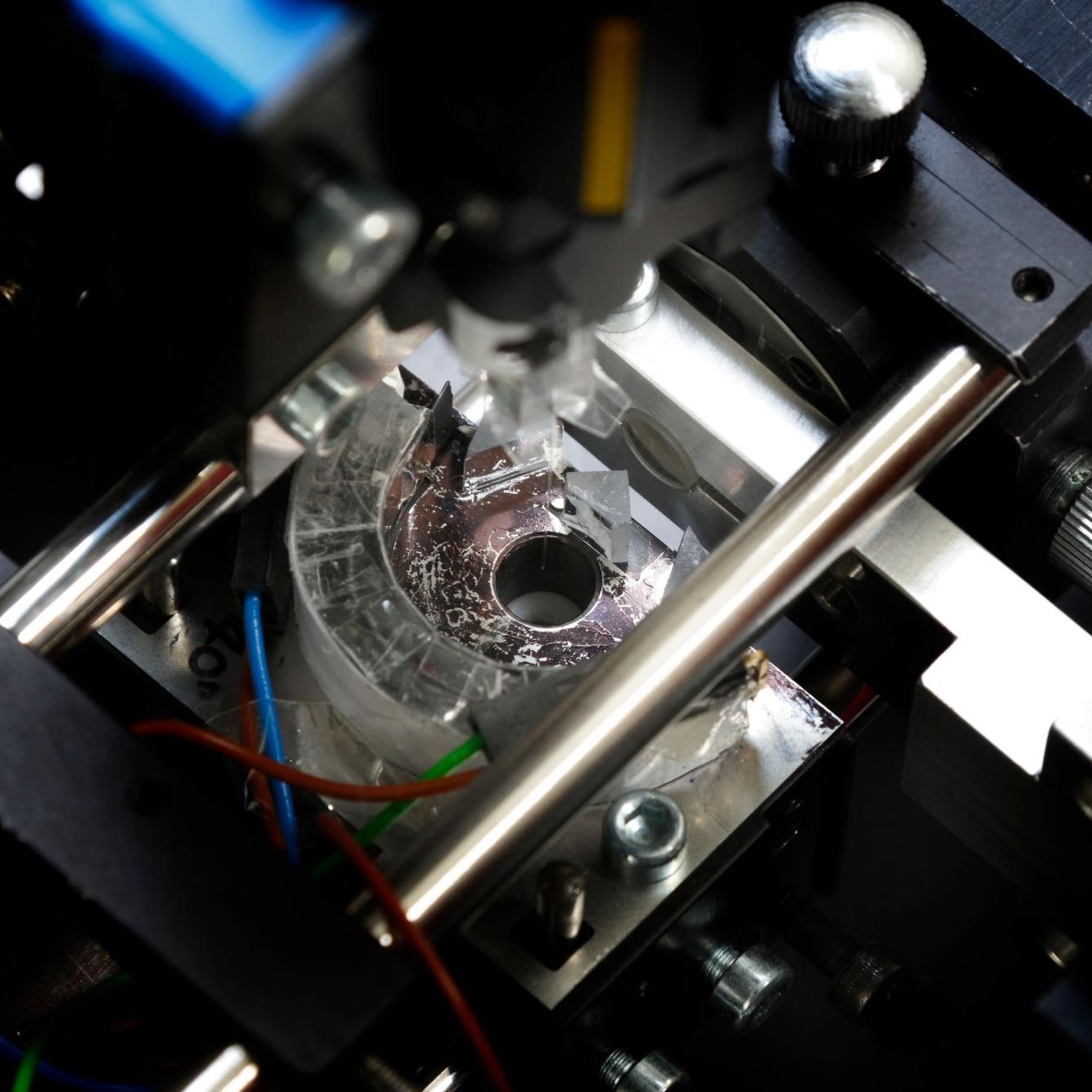

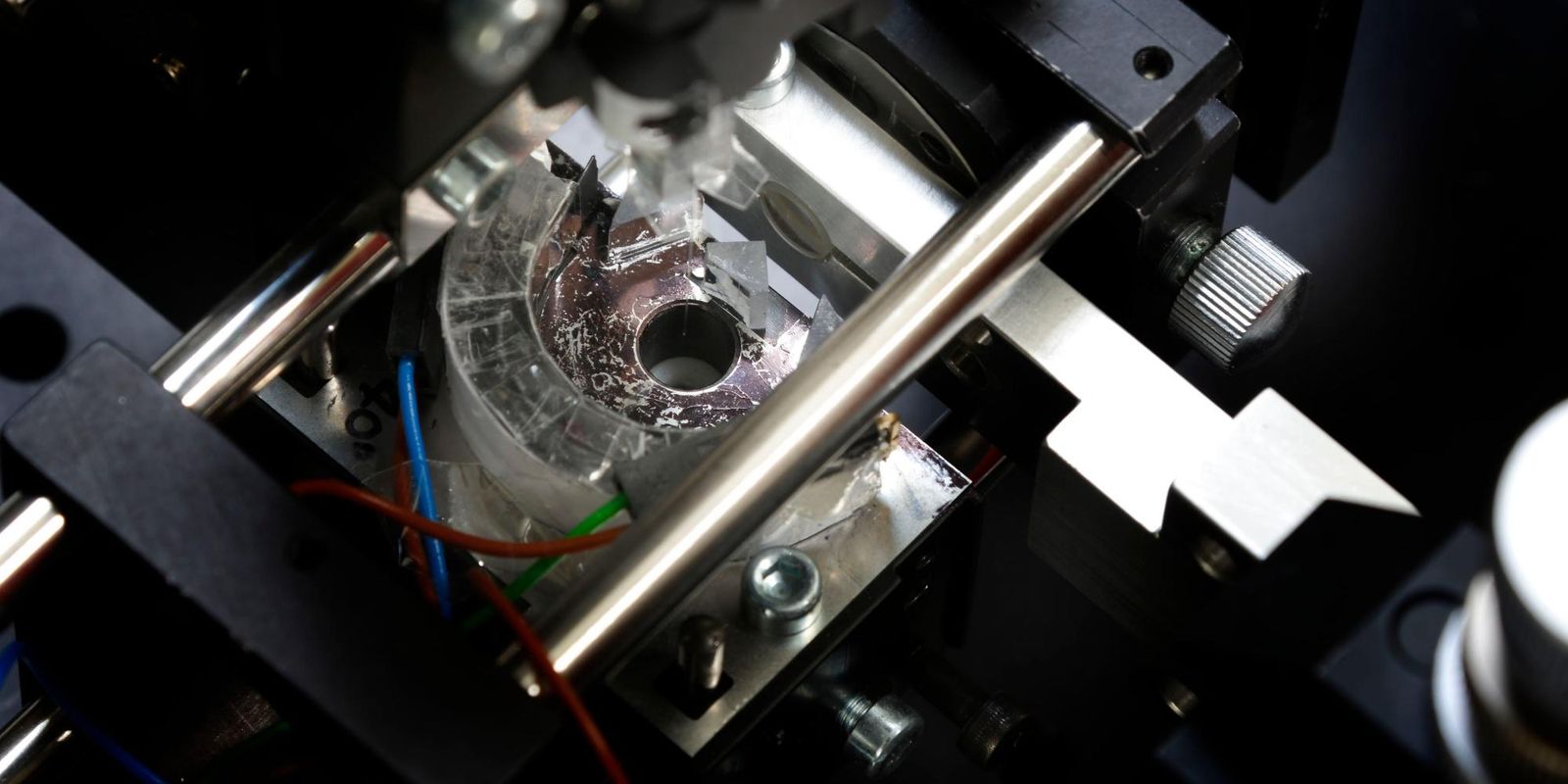

For a new machine that illuminates wafers in a high vacuum, we developed a short-stroke wafer stage. Within a wafer positioning system designed for maximum throughput and positioning accuracy, the stage’s movement has to be controlled with sub-nanometer resolution. For this, we came up with a special metrology solution: a metro-frame that enables position measurement with feedback to the wafer positioning system. We used high-efficiency linear electromotors, for which we devised an ingenious solution to achieve actuation in six degrees of freedom.

manufacture and qualification.

The stage design was subject to strict electromagnetic requirements. Therefore, we designed the stage’s motor housing as a complexly shaped, tightly toleranced cylinder to perform the function of a magnetic shield. Together with manufacturing partners we developed a sophisticated manufacturing process for sheets made of so-called mu-metal, a nickel-iron alloy. This involved laser cutting, laser welding and annealing to remove all mechanical tension for an optimal magnetic shielding. We took care of production, plus qualification, of the complete short-stroke wafer stage, including the special housing.

"we optimized our design for cost, assembly and maintenance."

We assumed responsibility from concept development to serial production. To optimize our design for cost, we weighed off the technical specifications against the cost of components such as sensors. We followed a design-for-assembly and design-for-maintenance approach. The focus was on safeguarding the cleanliness of the components and integrating the complete stage as an easily swappable unit into the customer’s system. This was particularly challenging because the system’s small footprint restricted the available volume.

more cases & tech insights.

measuring the nearly unmeasurable.

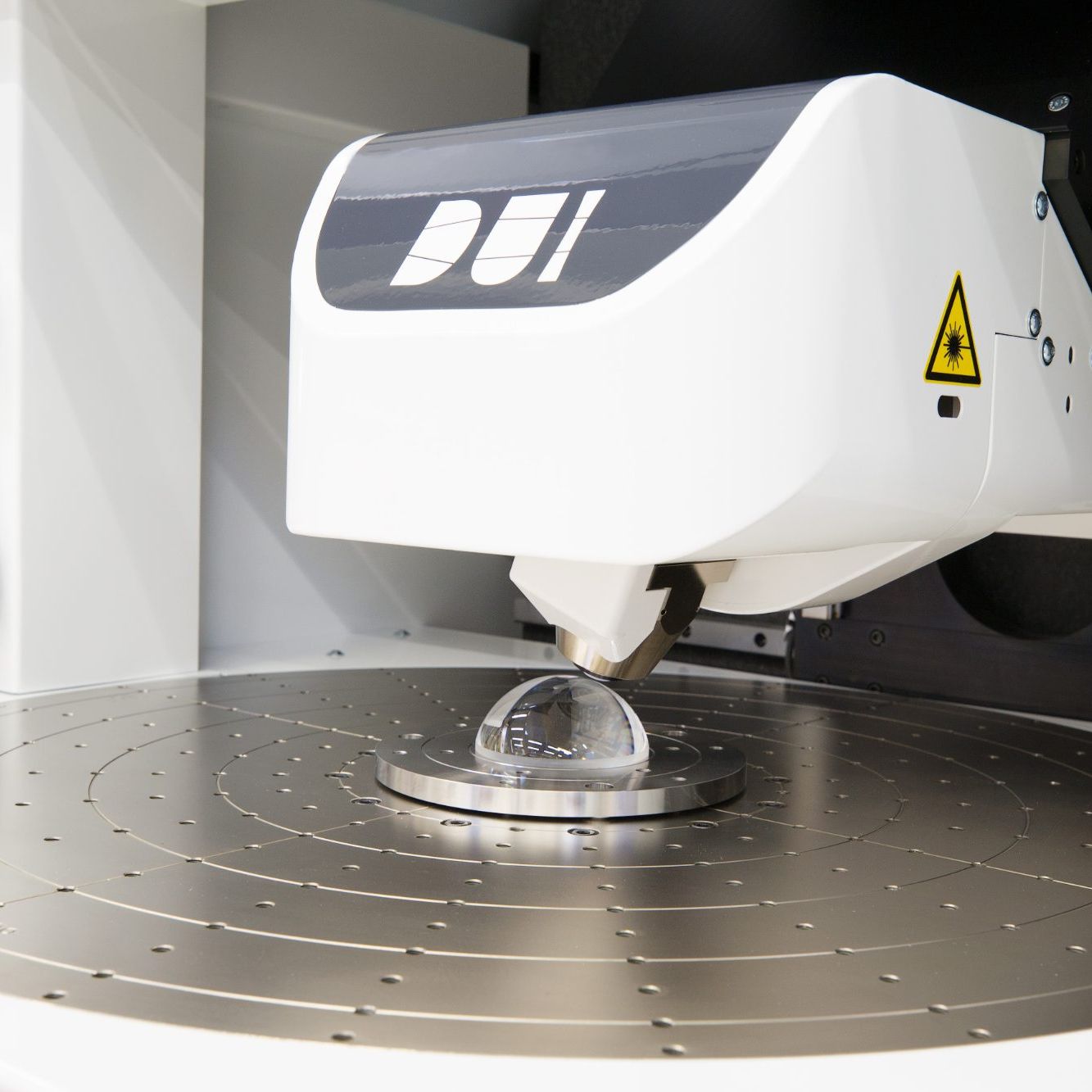

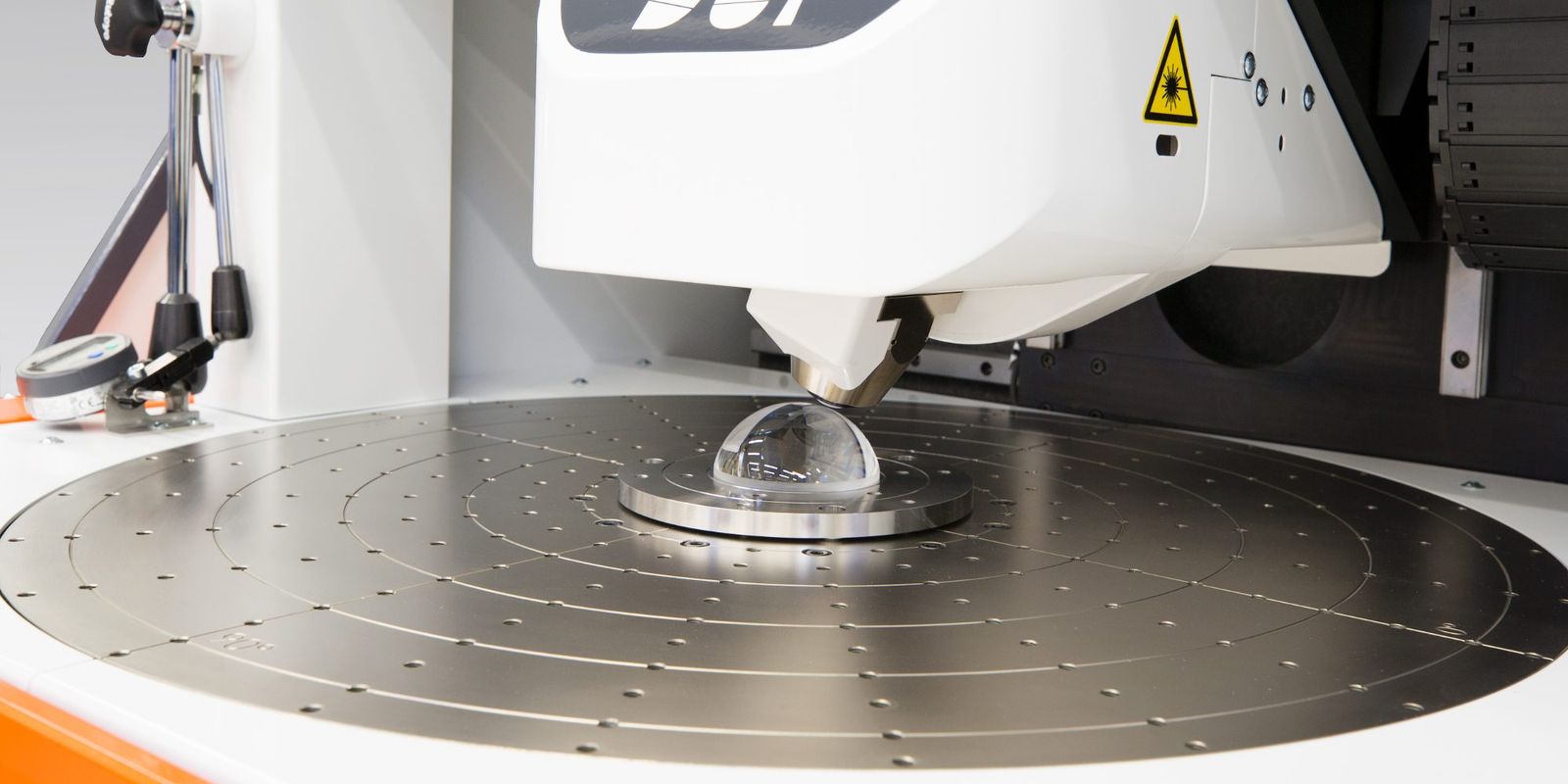

Conventional spherical lenses suffer from spherical aberration. Therefore freeform – often aspherical – lenses have become popular in lithography, aerospace, astronomy and microscopy as well as in (smartphone) photography.

Read more

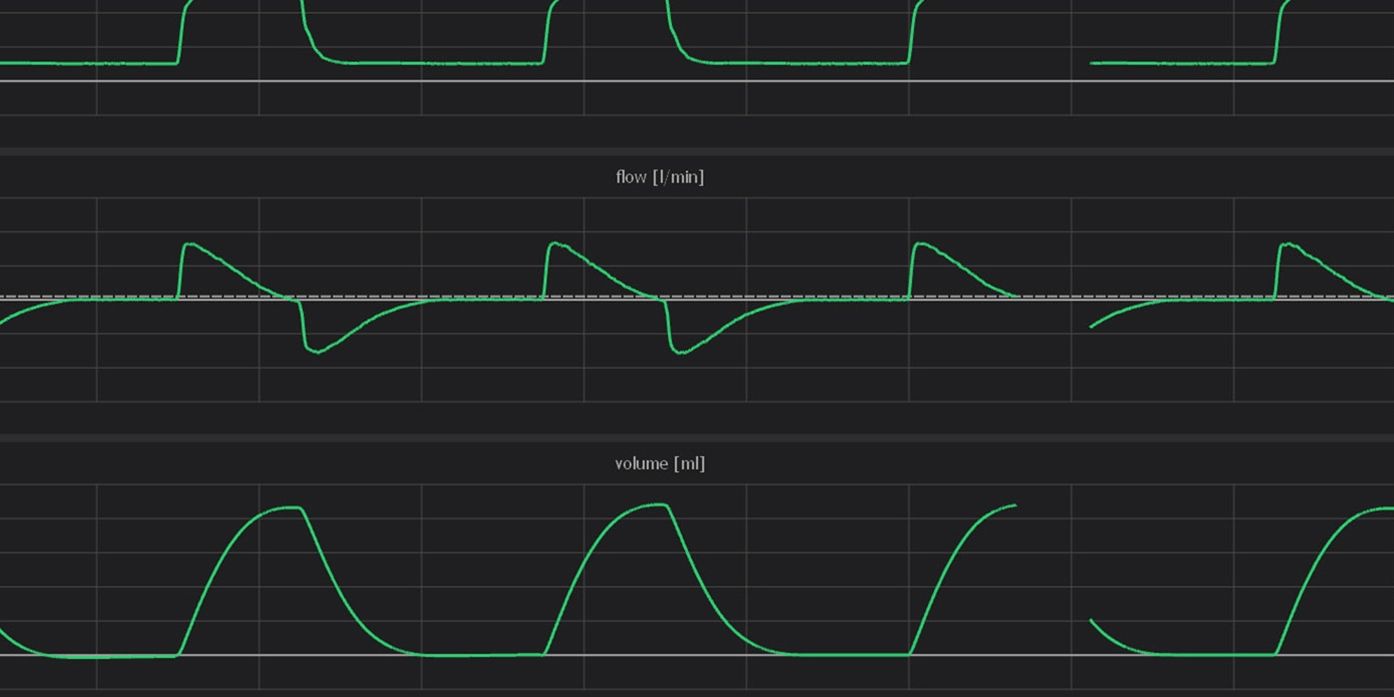

use cases in machine learning for time series.

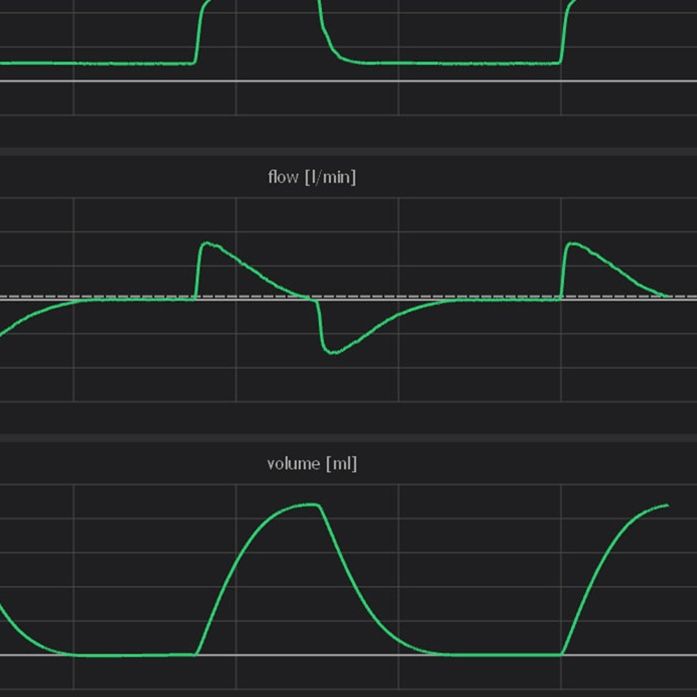

It is essential that the ventilator support is synchronized (in time) with the patient’s spontaneous breaths. A mismatch in this timing is referred to as Patient-Ventilator Asynchrony (PVA). To improve the patient’s comfort and recovery this PVA must be prevented. A key step in this process is the detection and classification of PVA.

Read more

glassfiber connection made easy.

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

producing medical radio-isotopes with minimal nuclear waste.

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more