highlights

• close cooperation with the customer

• many technologies integrated

• compact design

• robust tool

• easy to operate

highly integrated, robust device.

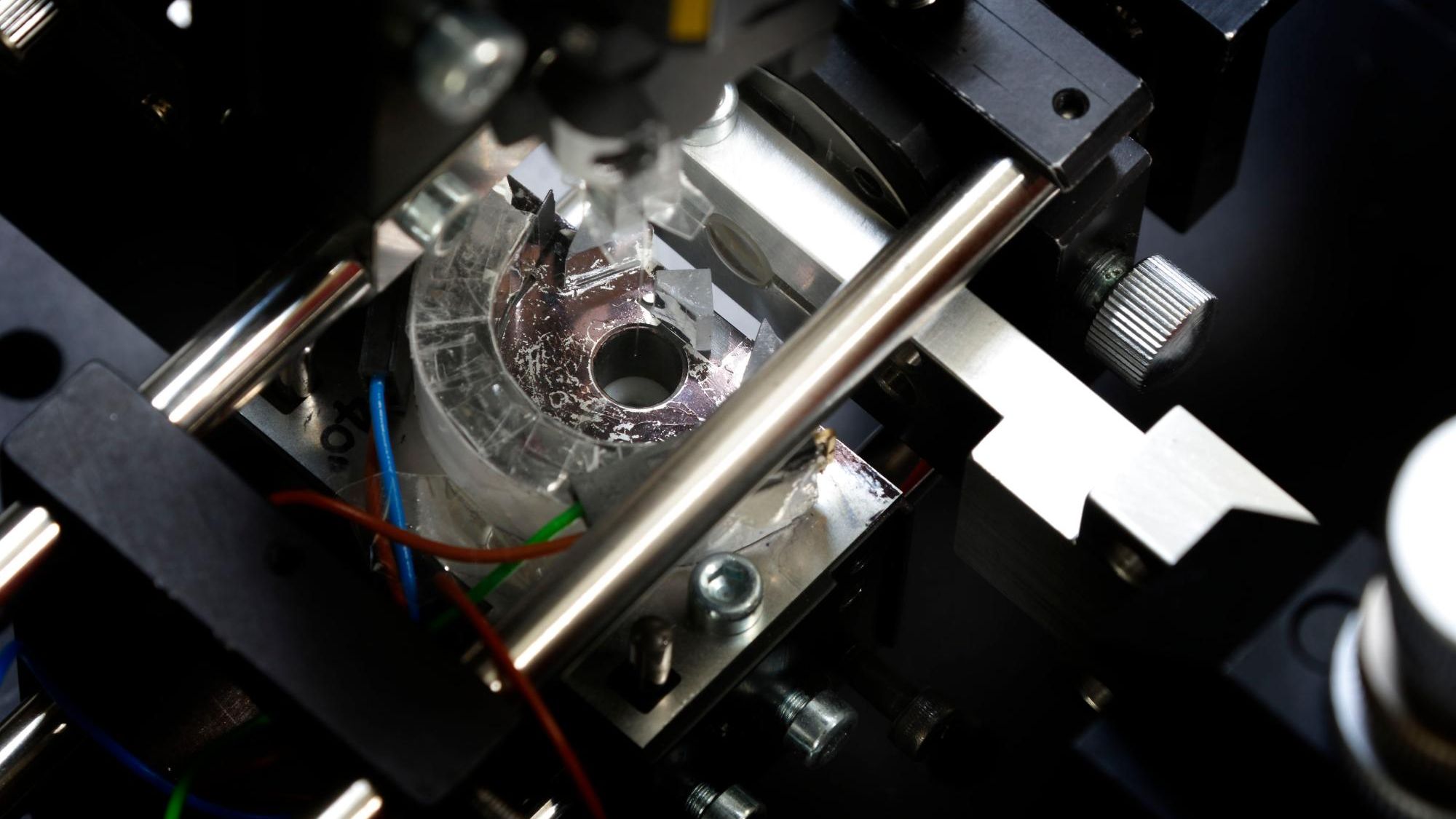

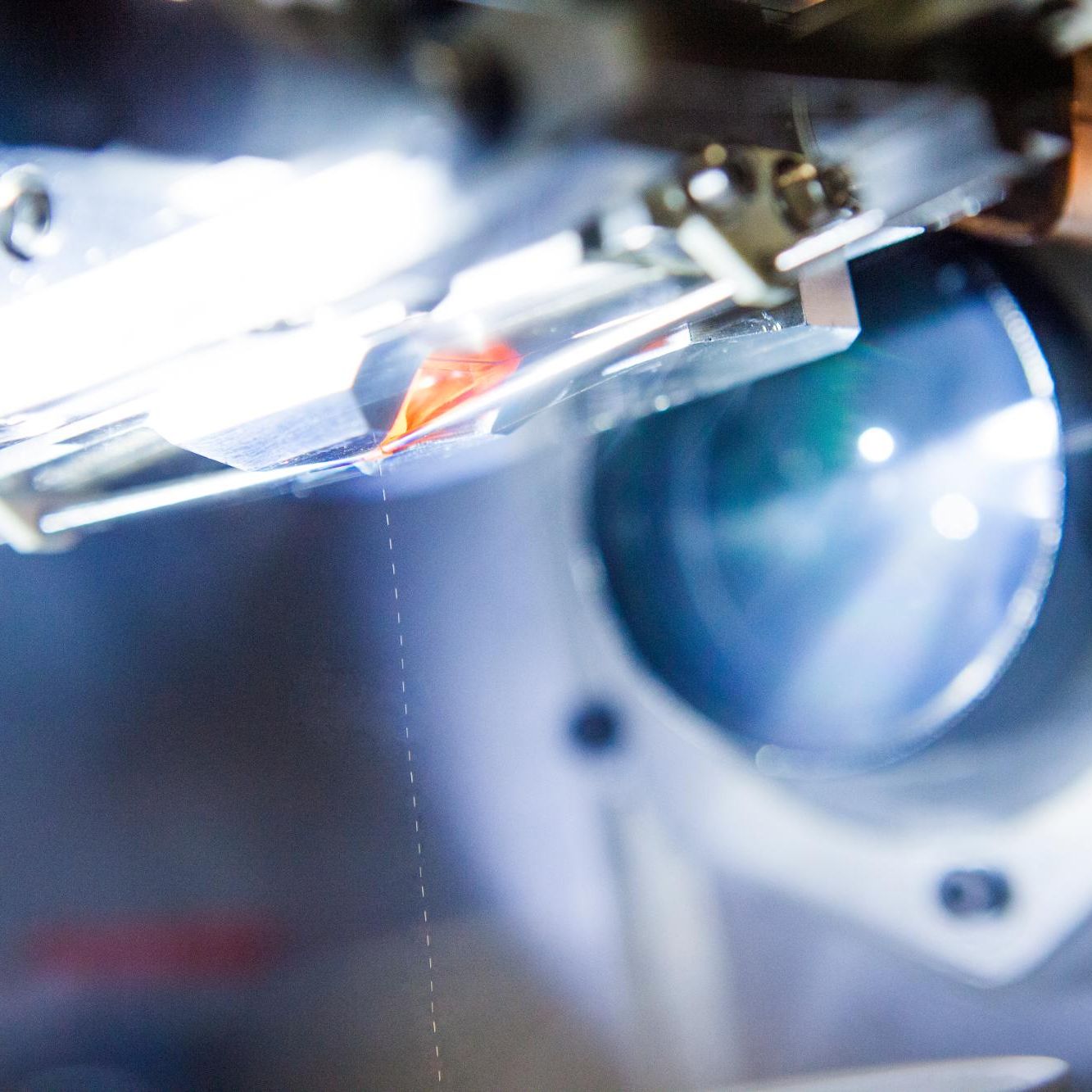

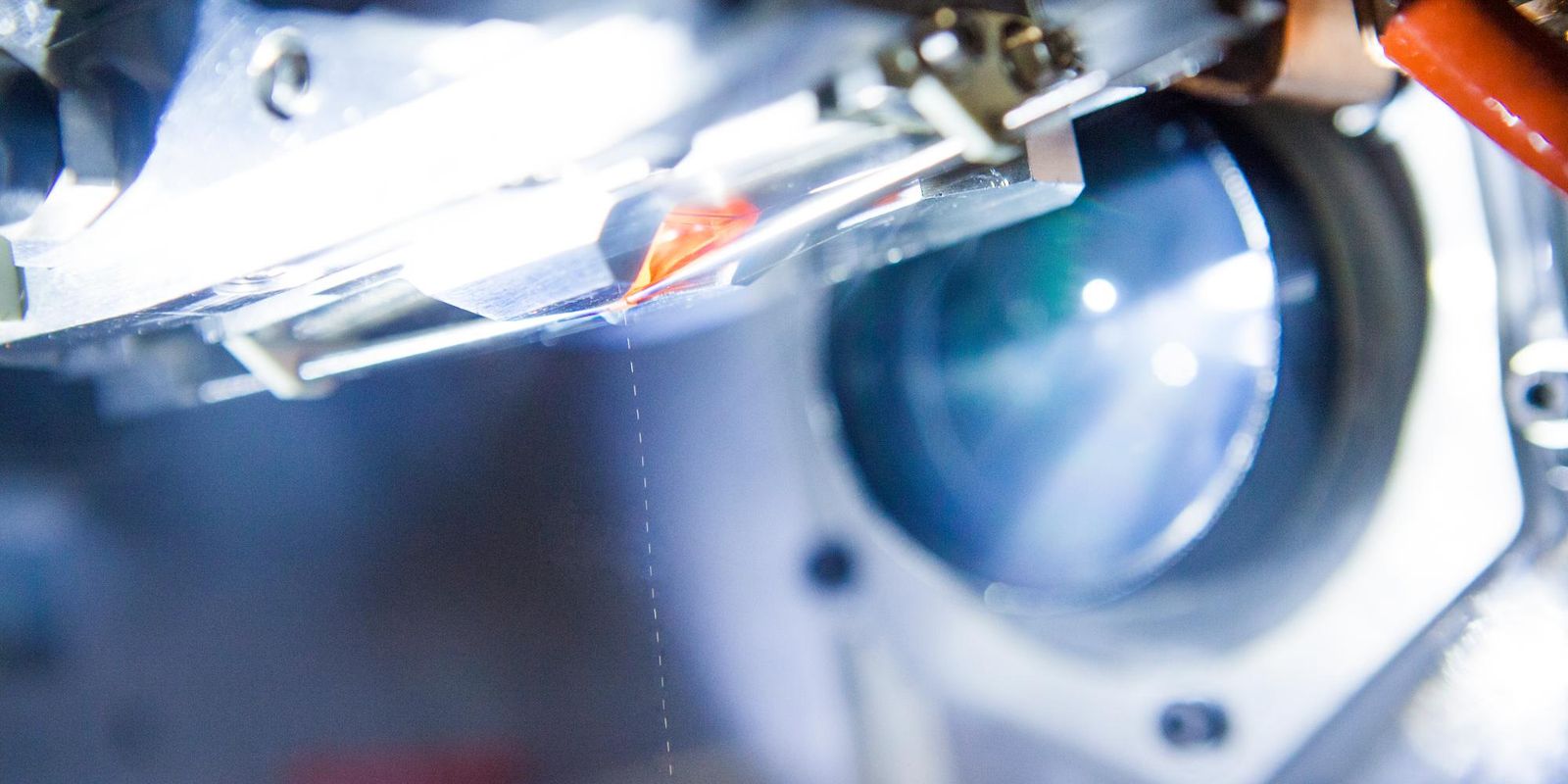

We love challenges like these. How do you integrate cutting, stripping, cleaning, cleaving, plasma treatment, inspection and connector placement into a handheld, one-hand-operated tool? Moreover, the tool had to be universally compatible with a variety of fiber-optic cable vendors. On top of that, the tool had to be very robust and easy to use. Close cooperation with TE Connectivity led to the desired robust design, resulting in high process yield, thanks to the use of the six sigma technique.

We built a test setup that allowed TE to validate all concepts and design proposals. The processes had to be robust without built-in checkpoints, as the tool lacked the space for that. Next phase: miniaturisation and simplification. Several prototypes were manufactured in-house, which TE Connectivity deployed for demonstration with customers. Last but not least, Demcon supported TE Connectivity subsequently with cost price optimization for series production.

handheld factory.

The number of different functions we integrated into such a small system was unprecedented. It resulted in a ‘factory in a box’. Through this project, we gained a lot of experience with hand-held mechatronic devices. The same goes for the accuracy in fiber positioning. We control the tip’s position at all times without (camera) vision technology. This might prove useful in medical applications, for instance with needle steering.

The analysis of suitable manufacturing techniques in close collaboration with TE Connectivity is a delivery from the European VECTOR (Versatile Easy installable Connector implementing new Technologies for accelerated fiber Optic network Roll-outs) project.

"robust cooperation."

We developed an entirely new tool with many technologies integrated into it. Our mechatronic systems engineers ensured a smooth transfer of the development work to the various disciplines. We are proud that we managed to realize this true mechatronic systems design with a high degree of miniaturization in close cooperation with the people at TE Connectivity.

more cases & tech insights.

Hot head on a cool stage

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

Hemics HandScan: fast, painless and objective screening for rheumatoid arthritis

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more

Producing medical radio-isotopes with minimal nuclear waste

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more