OUR SERVICES

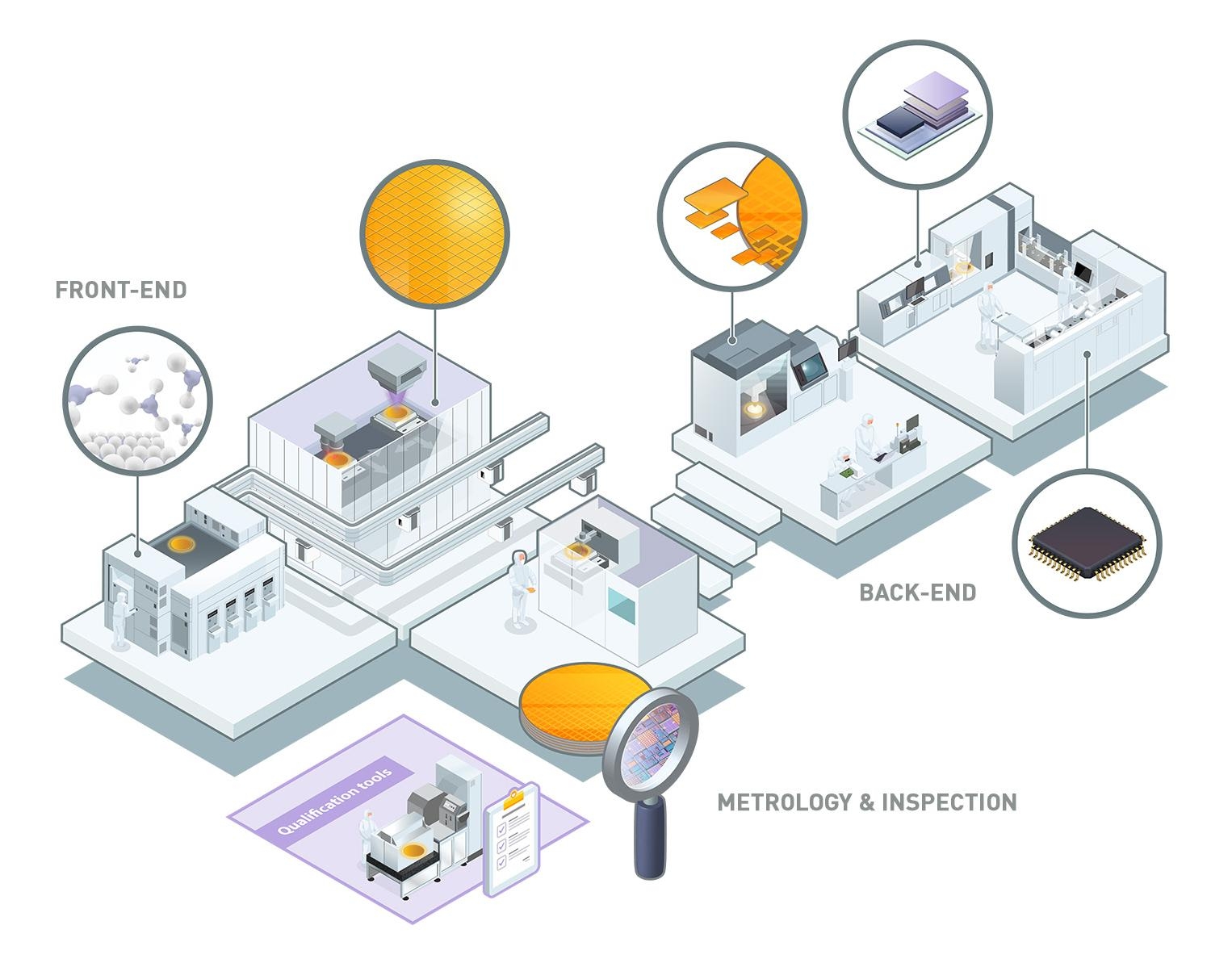

With a constant drive for miniaturization, higher speed and lower cost, chip manufacturing is an ongoing challenge that pushes the engineering envelope. For the entirety of our history, semiconductor production equipment has been one of our strong suits. Both in front-end and back-end as well as in metrology and measurement tools. We have a long track record, developing and realizing customized modules and machines for many of the world’s biggest OEM’s in semicon equipment. Our scope stretches from positioning and deposition modules to mask and wafer inspection tools, extending to advanced packaging solutions.

We offer end-to-end engineering as a service for semicon manufacturing equipment, from early-phase research and concept development to prototyping, validation and production. Customers can pick and choose the extent of our involvement. We will balance out performance, cost of ownership and time to market, according to your specific demands.

With our experience in developing positioning systems for semiconductor equipment for the EUV node, we have developed a technology platform. This platform consists of a library of technologies, components and sub-modules that can be combined into a customized ultra-high precision substrate positioning system. The availability of these libraries strongly reduces the development time and costs of customized nanometer-precision stages.

Demcon offers end-to-end engineering as a service for semicon manufacturing equipment, from early-phase research and concept development to prototyping, validation and production. Customers can pick and choose the extend of our involvement. We will balance out performance, cost of ownership and time to market, according to your specific demands.

We believe in the power of partnerships. So, to deliver as promised, we combine expertise, experience, and domain knowledge to create a winning team. Working side-by-side, creating shared value.

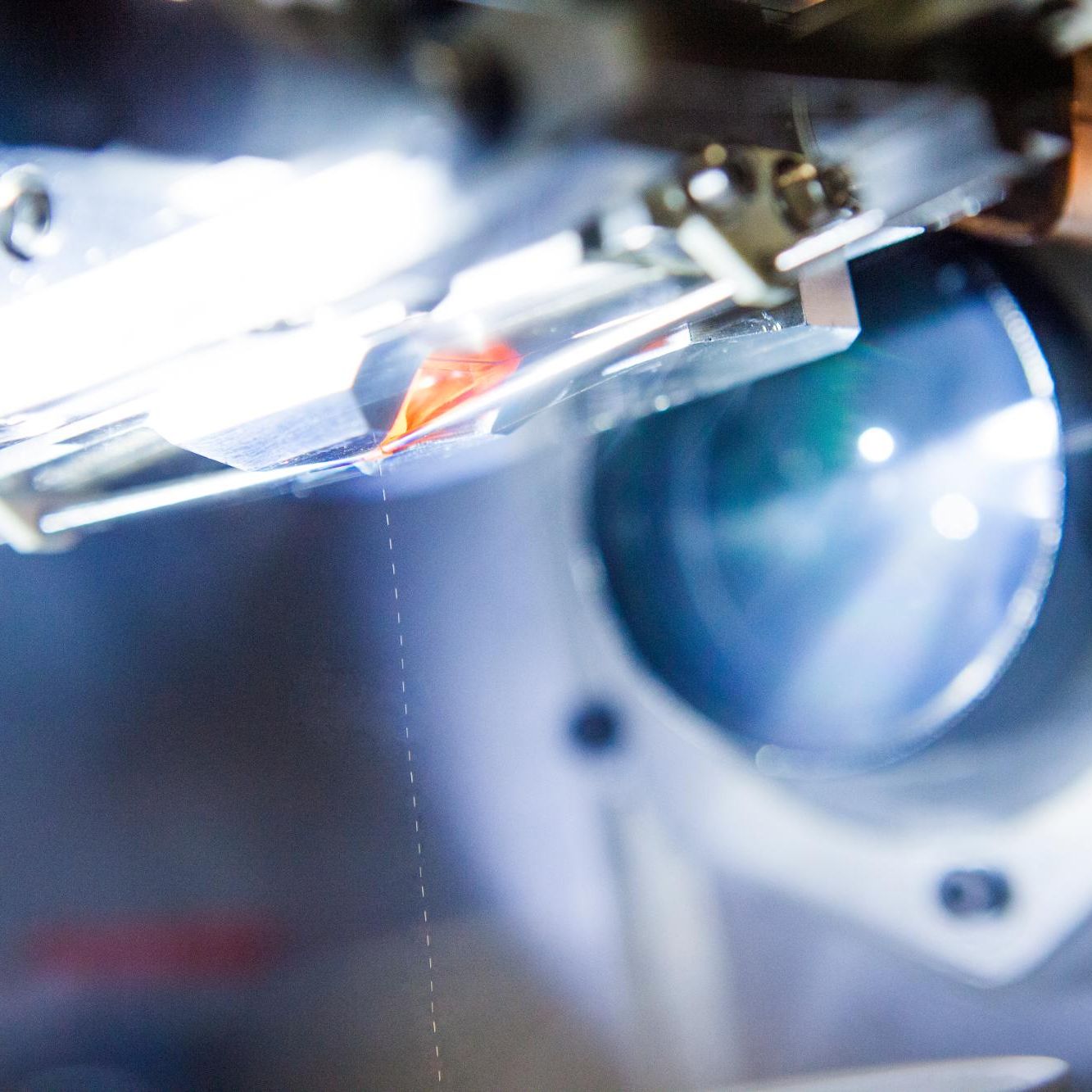

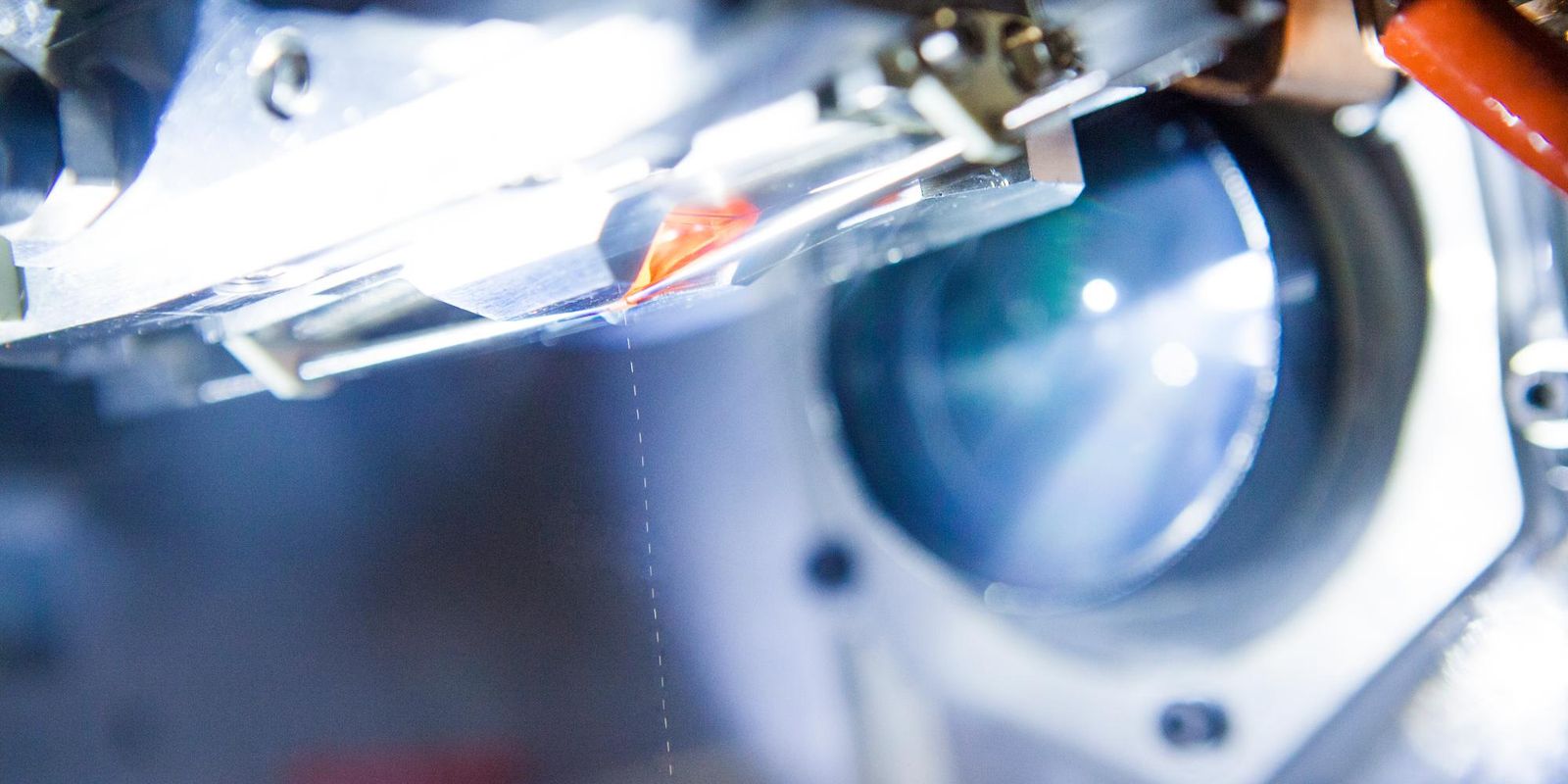

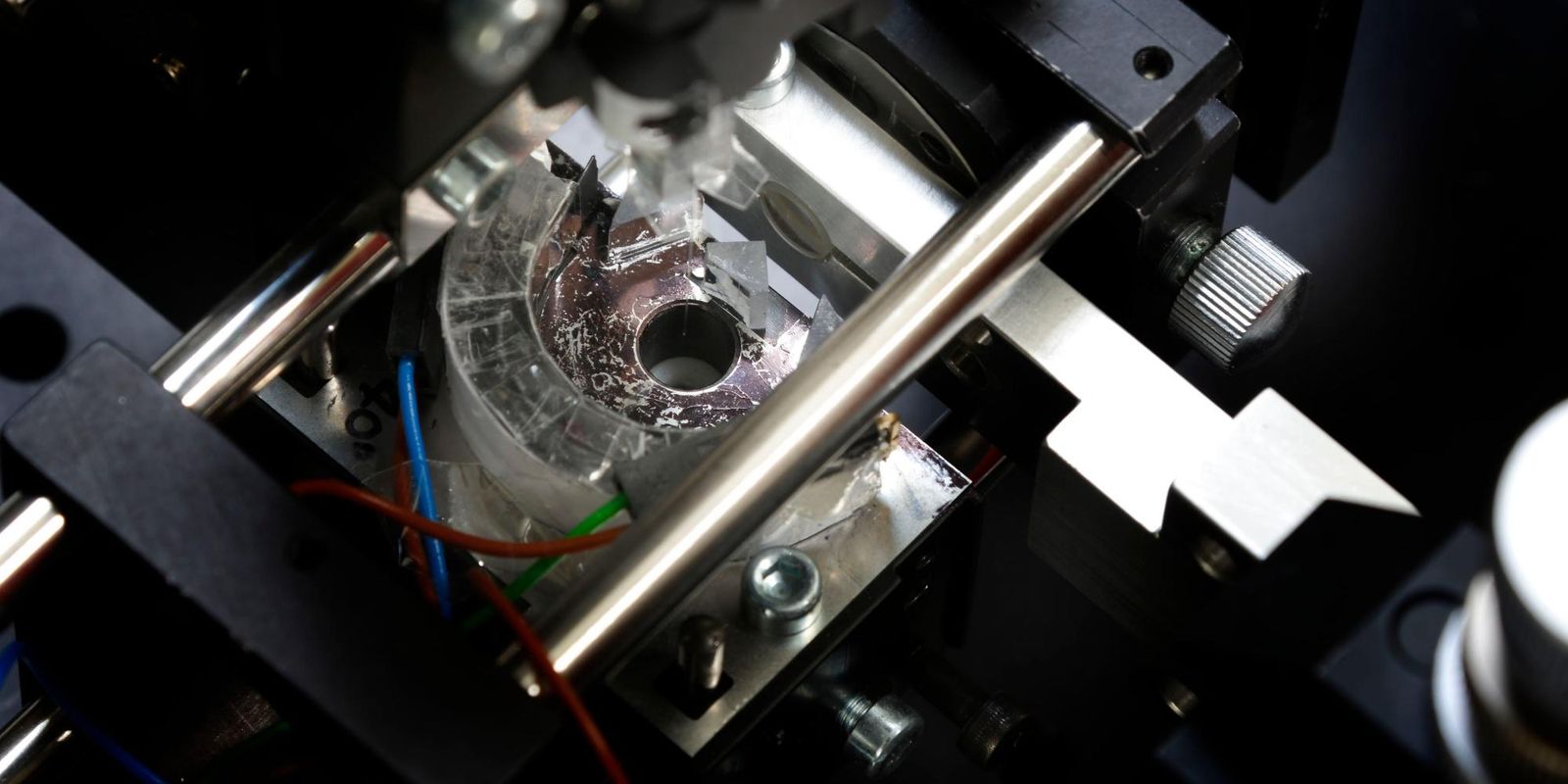

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

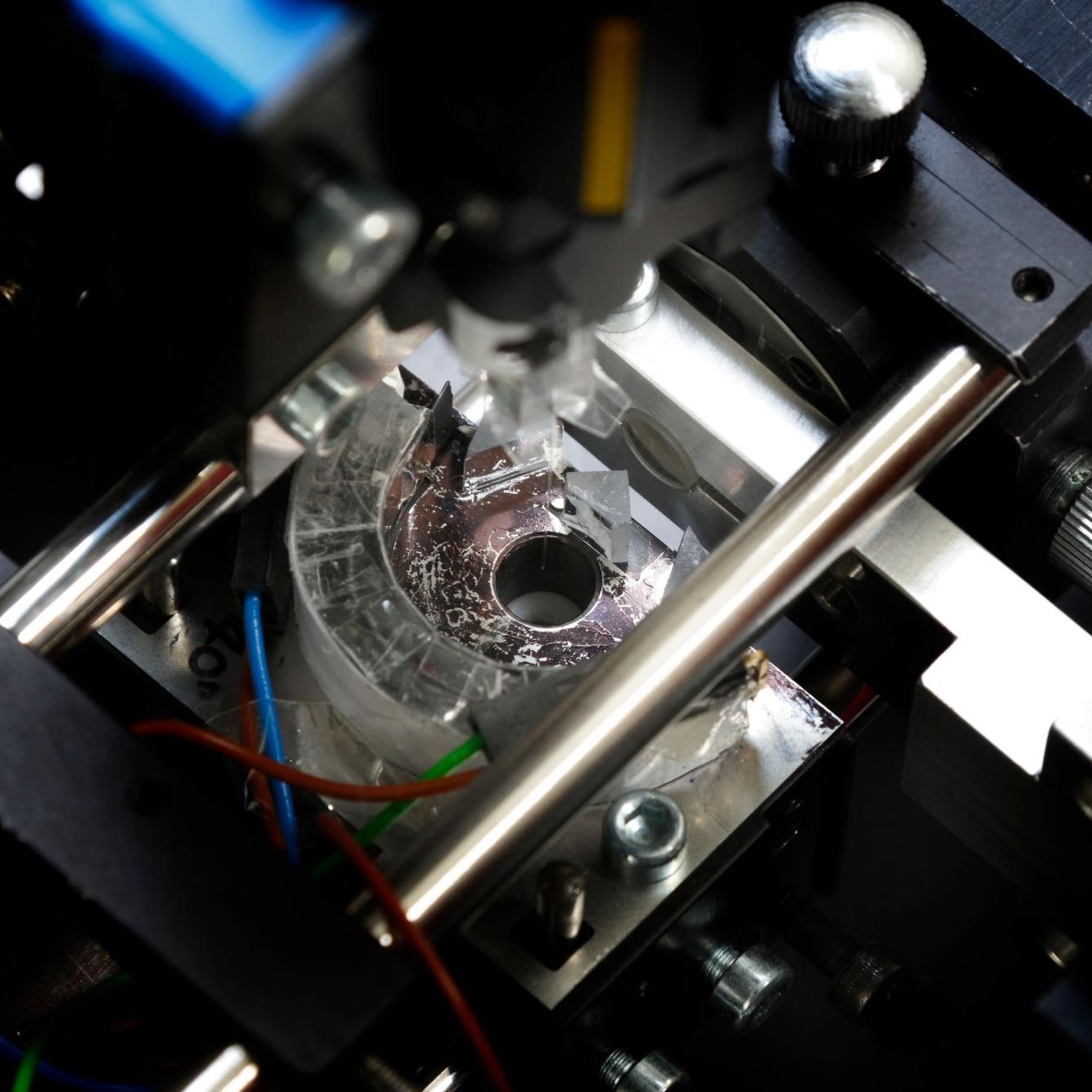

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more