nanoLEV

ultra high-precision stage.

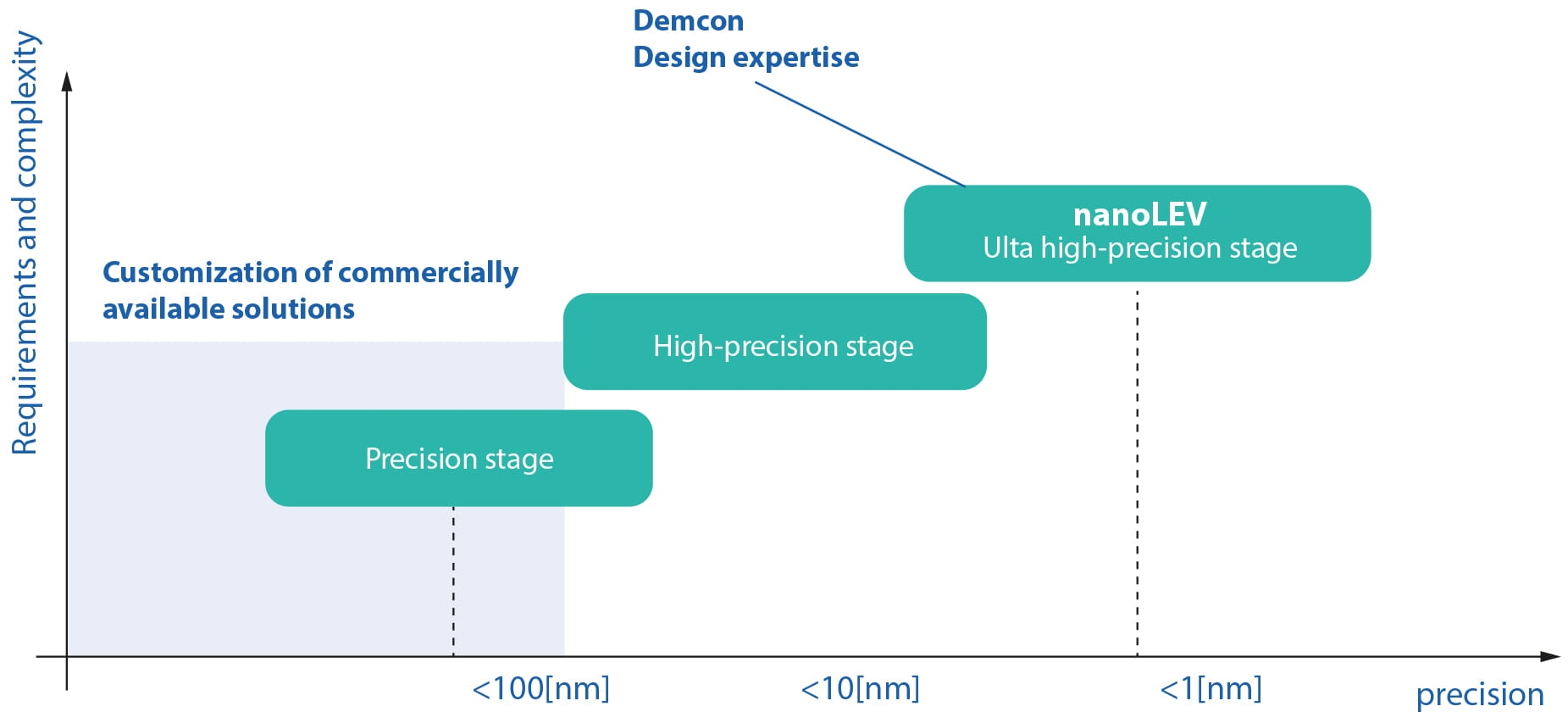

With our experience in developing positioning systems for semiconductor equipment for the EUV node, we have developed a technology platform. This platform consists of a library of technologies, components and sub-modules that can be combined into a customized ultra-high precision substrate positioning system. The availability of these libraries strongly reduces the development time and costs of customized nanometer-precision stages.

We design for your needs

Based on the nanoLEV platform, we customize the design to your specific needs:

- Nanotesla magnetic field compliant

- Low outgassing design for a vacuum environment

- Low particle design for substrate contamination

- Design to pay-load, acceleration and velocity requirements

- Comply to mechanical interfaces and volume claim

- Comply to customer-specified software and electrical interfaces

our design capabilities.

nanoLEV can meet the most stringent requirements for dynamic positioning by applying proven control concepts for long stroke and short stroke positioning. We combine structural FEA of our stage design with control algorithms and simulation to fully evaluate our mechanical and control design to your system requirements before hardware is built.

Our software engineers can implement the control algorithms on the platform of your choice. Or from our existing real-time OS experience, including FPGA real-time analog and digital data acquisition solutions.

nanoLEV includes solutions for thermal management at nanometer accuracy. E.g. low thermal load on yout substrate by gravuty offset and optimization of actuator design. Further we design with low thermal expansion materials and apply inline algorithmic corrections to achieve the ultimate positioning specifications for your application.

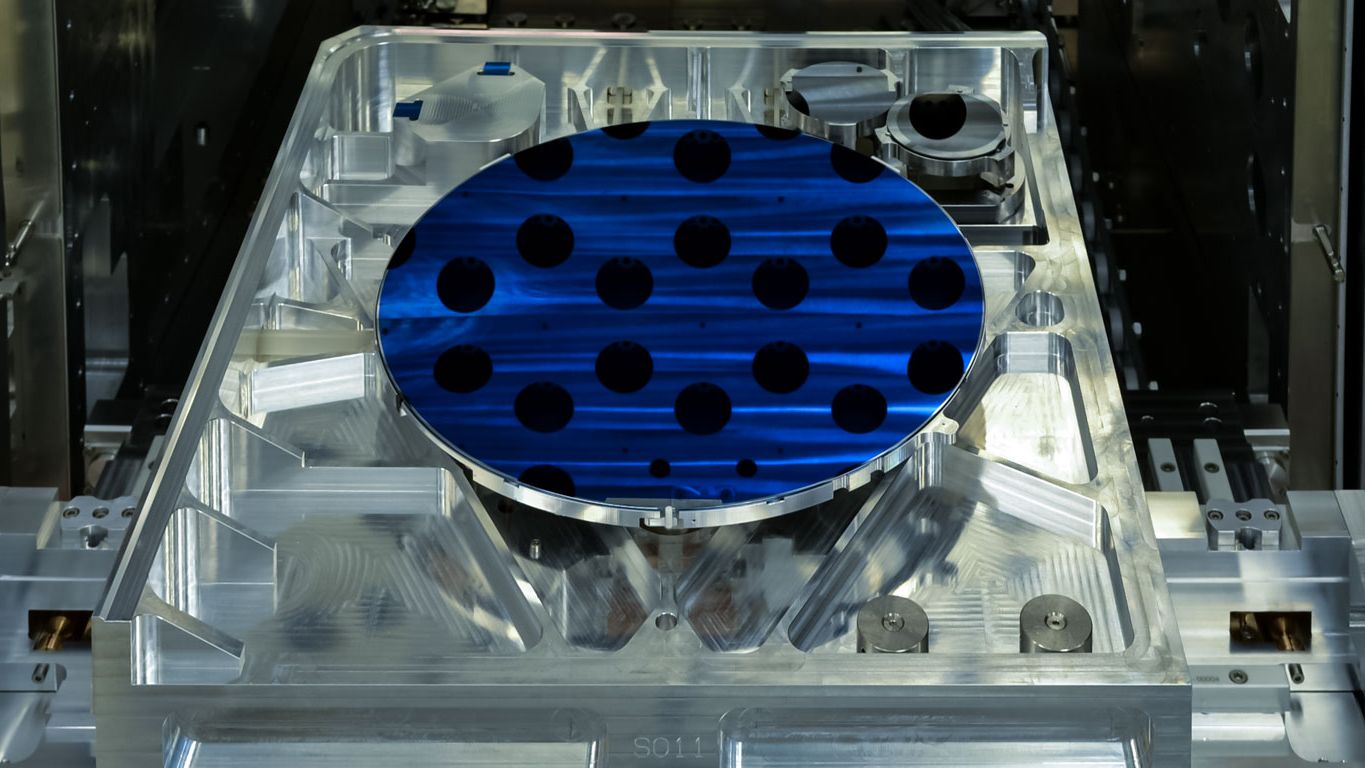

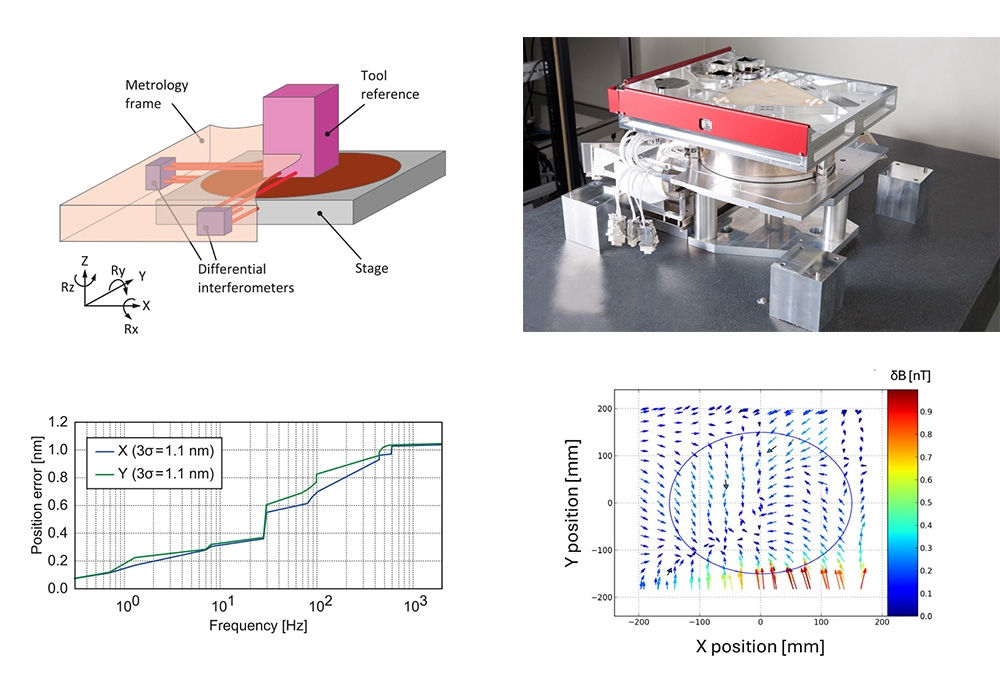

The ultra-high precision stage is a 6 DOF short-stroke magnetic levitation stage, which is built on top of a traditional 3 DOF XY-stage with ball - or air bearing technology.

f.l.t.r.: 1) Stage metrology 2) nanoLev short stroke 3) Stage XY positioning error [nm]

4) B-field for moving stage in [nT]

maximum degree of freedom.

We offer flexible co-development arrangements to suit your needs. We have comprehensive stage design and production capabilities.

However, we can also collaborate with your existing suppliers to provide the required design solutions, ensuring optimal use of your supply chain.

Beyond our expertise in system-level design for positioning systems, we offer additional services to meet your specific needs.

- Translating imaging system requirements to stage performance requirements

- FEA for vibration propagation evaluation and vibration isolation design

- Metrology solutions for nanometer-accurate substrate alignment

- Stage calibration sequence to achieve nanometer precision

- Positioning system assebmly, integration and verification

| Platform specifications | Proven (extendibility) |

|

Range X, Y, Z |

350 x 350 x 1 [mm] (500 x 500 x 5 [mm]) |

| Footprint | 0.8 x 0.8 x 0.6[m] (-) |

| Maximum pay-load | 2.0[kg] (5.0[kg]) |

| Acceleration Velocity |

1[m/s^2] / (10[m/s^2]) 0.3[m/s] / (>1[m/s]) |

| Precision |

1.1[nm]@20[mm/s] (<1[nm] @500[mm/s]) |

| Accuracy Settling time |

25[nm] (<10[nm]) 150[ms] (<50[ms]) |

| Thermal load to substrate |

0.1[W] (0.01[W]) |

| Magnetic field change with stage movement |

1[nT] (<1[nT]) |

| Vacuum compatibility | 1e-6[mbar] (1e-7[mbar]) |

| Particles per pass |

Design for ≤ 1/40 @ >100[nm] |

| Reliability MTBF Lifetime |

Design for < 1[year] Design for > 7[year] |

your engineering partner

With over 25 years of experience in designing performance-critical positioning systems, we bring a first-time-right approach when developing your high-accuracy positioning system.