highlights

• mechatronics

• optics

• image processing and analysis

• black-box modelling, machine learning and AI

• clinical studies and medical device regulations

• production

how does the HandScan work?

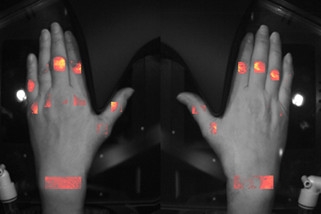

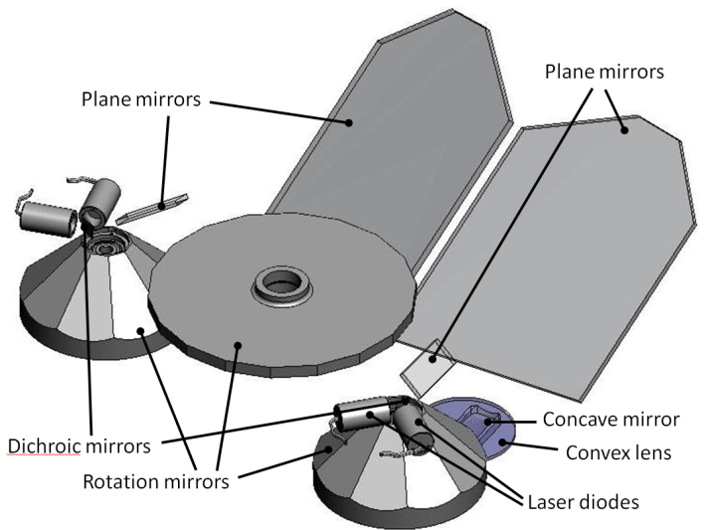

The HandScan uses a red and a near-infrared laser plus a system of rotating mirrors to create a scanning light spot underneath the hands. Cameras register light transmission through the hands. The contour of each hand and the approximate location of joints is automatically determined through image processing, and the laser spot is turned off outside the hand contour to prevent saturating the camera. During a measurement, a pressure cuff around each lower arm is temporarily inflated to obstruct venous blood flow back to the heart, and the resulting gradual changes in light transmission due to blood pooling give additional information about hemodynamic effects related to joint inflammation. Multispectral stacks of images captured during a measurement are processed and extracted parameters fed into inflammation models that output an inflammation score for each joint in the hand.

A data reduction of many orders of magnitude is first obtained by fitting the measured response curve of each pixel in a stack of images to a nonlinear mathematical model for hemodynamic response. This is followed by combining the extracted parameters of each pixel within a joint ROI (region of interest) and an (assumedly non-inflamed) reference ROI near the joint. This results in 10-20 parameters per ROI, and an automatically selected subset of less than 5 of these parameters forms the input for the inflammation scoring models. Reference data for training the inflammation scoring models is obtained from several clinical studies in which an expert ultrasonographer complements the raw image stacks of HandScan scans with target scores for use in supervised learning. Models are finally selected for clinical use based on their AUC value, a measure for the reliability of the inflammation scores. Inflammation scoring models can range from simple linear regression to multilayer perceptron networks in trade-offs between simplicity (minimizing overfitting risk) and accuracy.

what were our challenges?

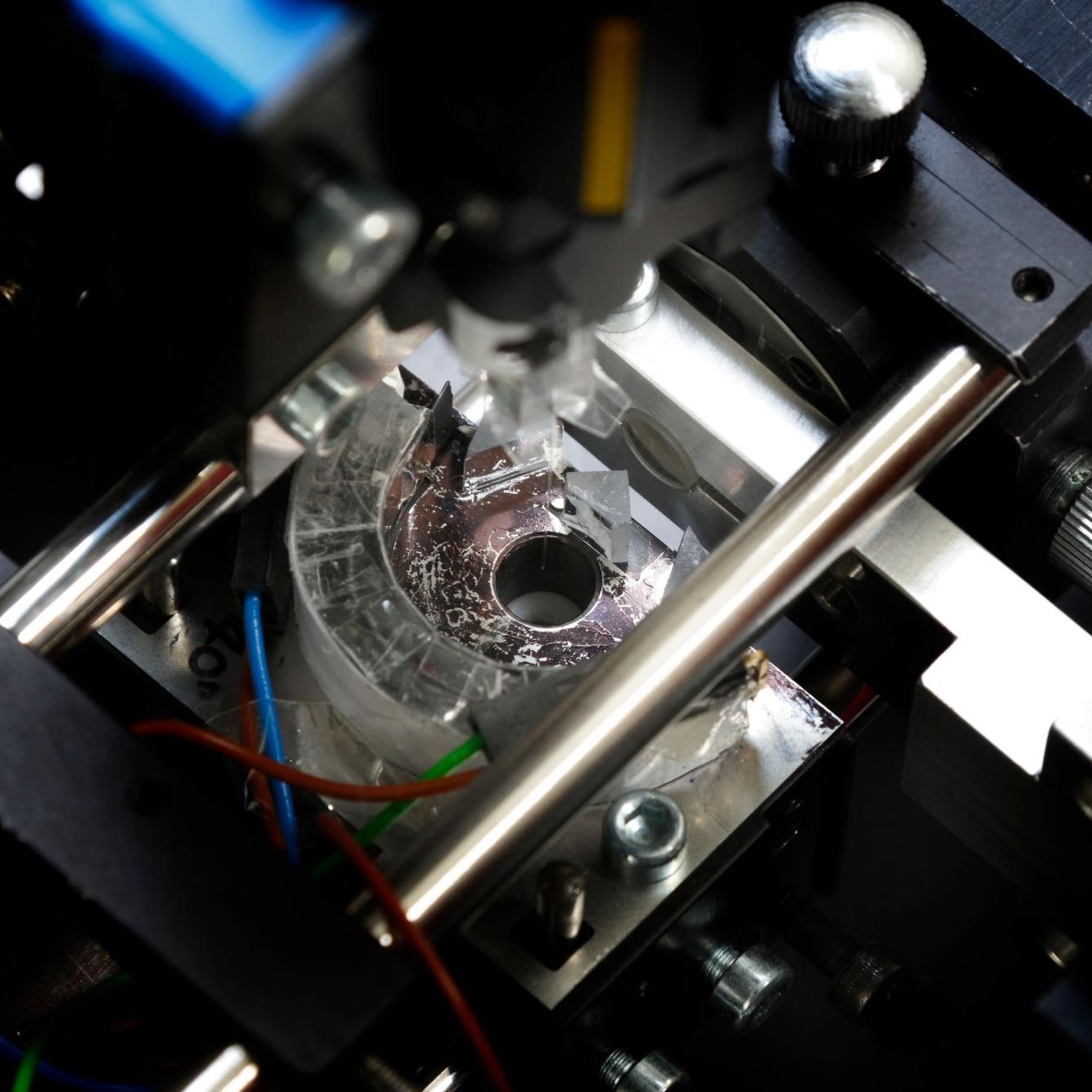

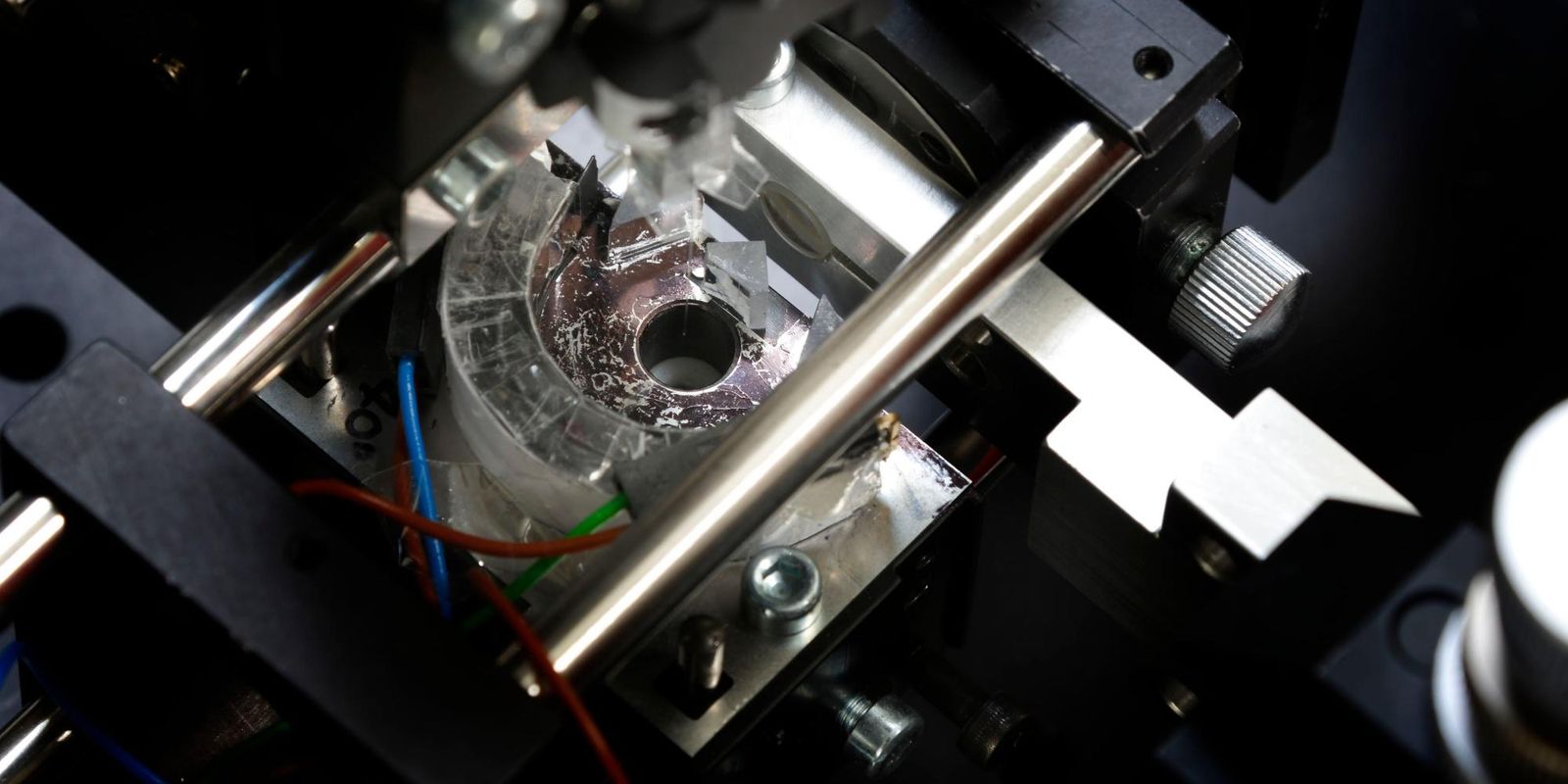

One of our main challenges in our role as development partner for Hemics was to ensure stable and accurate alignment of the scanning laser illumination pattern underneath both hands, using a combination of rotating mirrors and computer vision based switching patterns with the two lasers.

our role developing this system.

We were a development partner from the start. We were responsible for the concept design as well as the detailed design and documentation. In addition, we made the hardware prototype and accompanying software and are now responsible for production of the HandScan.

“glad with enthused patient reactions.”

A recent patient brimmed with enthusiasm about the HandScan. Patients value it to objectively see what they feel in their joints and see this imaging device as a considerable added value to disease monitoring. For us it is great to see how happy patients are with it.

more cases & tech insights.

Hot head on a cool stage

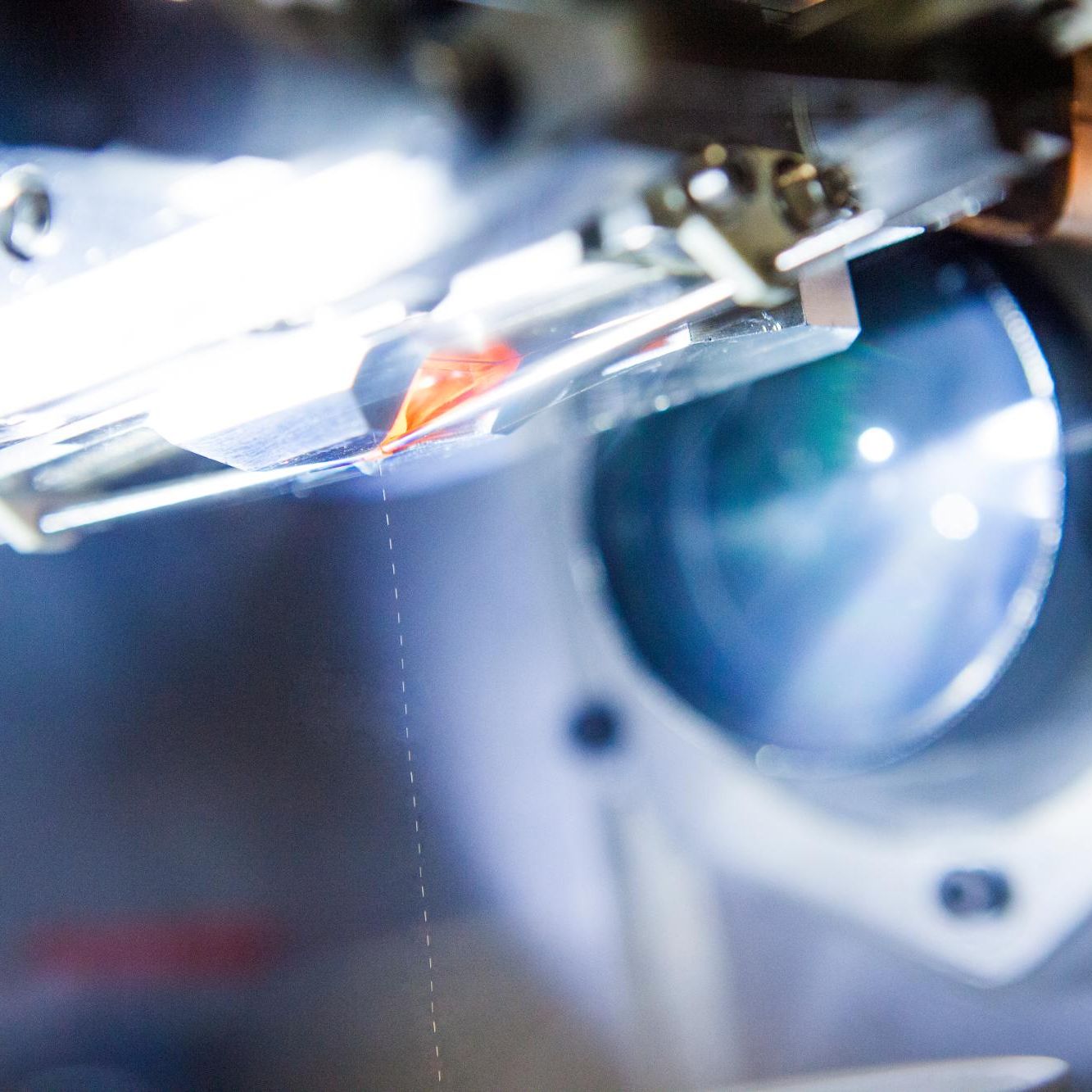

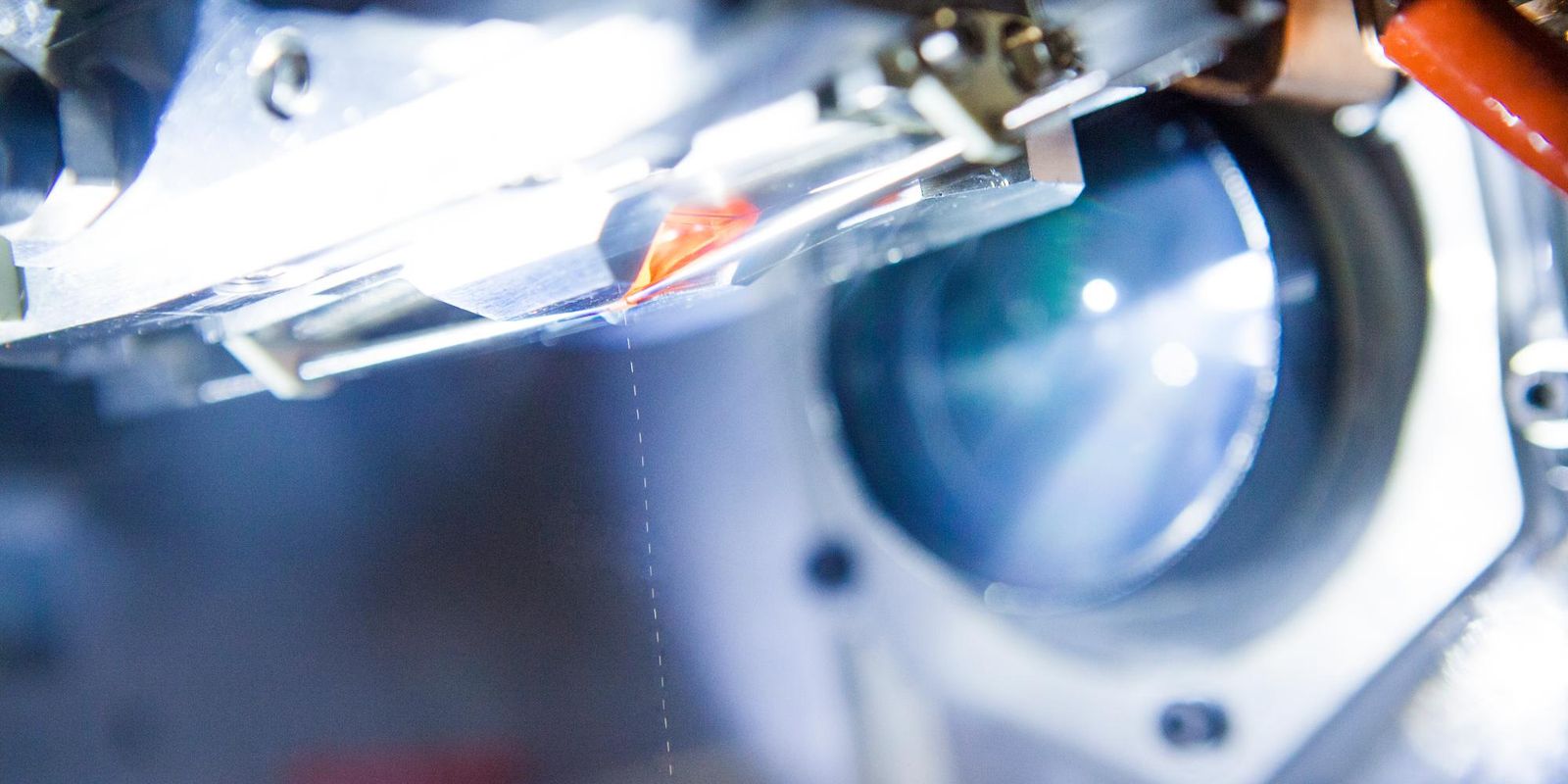

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more

Producing medical radio-isotopes with minimal nuclear waste

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more