highlights

• thermodynamic simulation for temperature control

• high accuracy positioning systems

• development of dedicated control software

• a fully functioning metal jet printer

• meticulous temperature control

integrated solution.

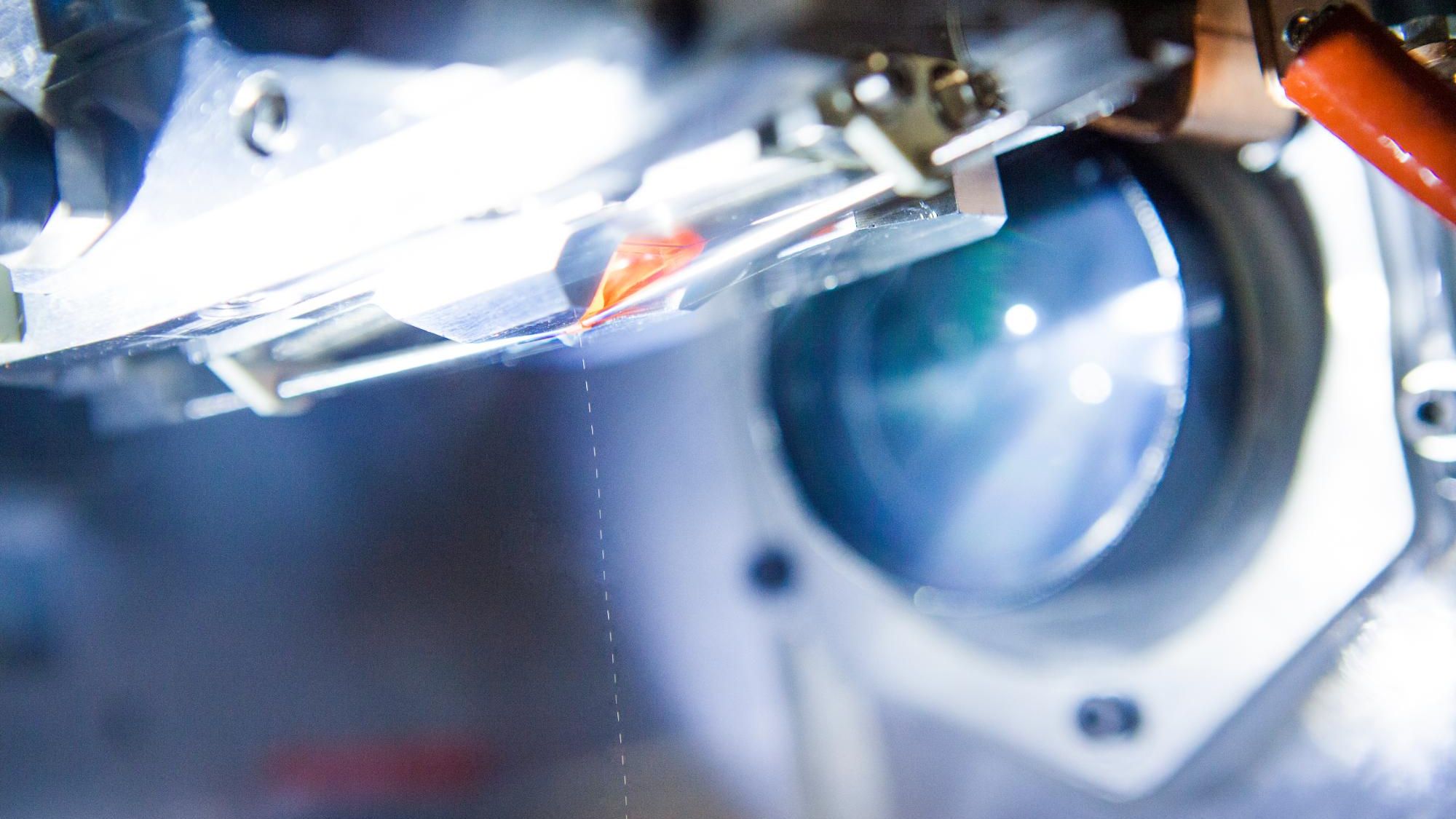

At the University of Nottingham the interactions between droplets and substrate, and droplet to droplet, needed to be studied in order to develop the MetalJet process.

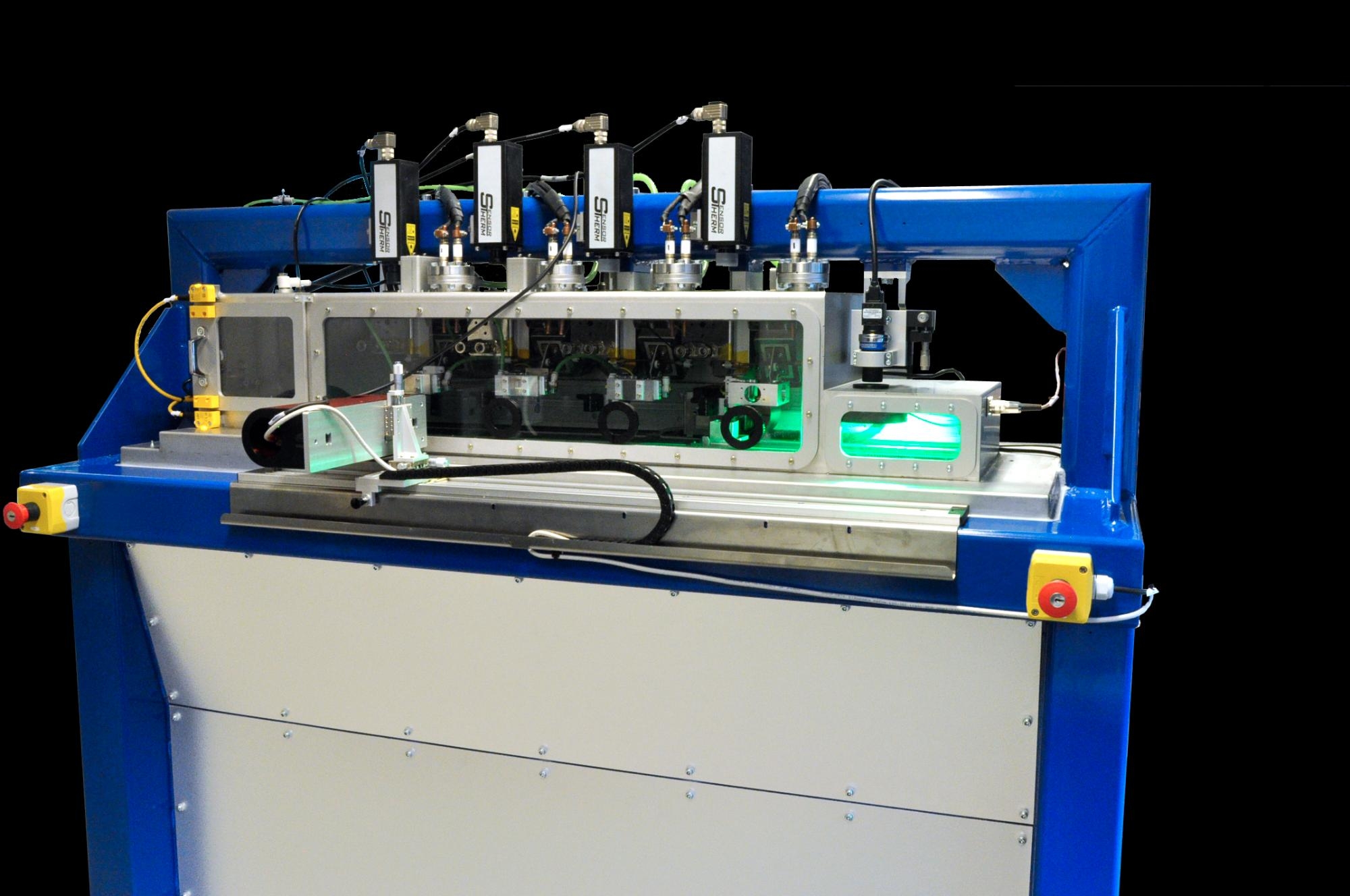

This asked for adding components such as cameras to verify and align droplet placement. A heater and coolers for temperature control around the print head were indispensable. On top of that all, custom software was written to regulate printer start-up and printing, including loading all layers of a 3D print.

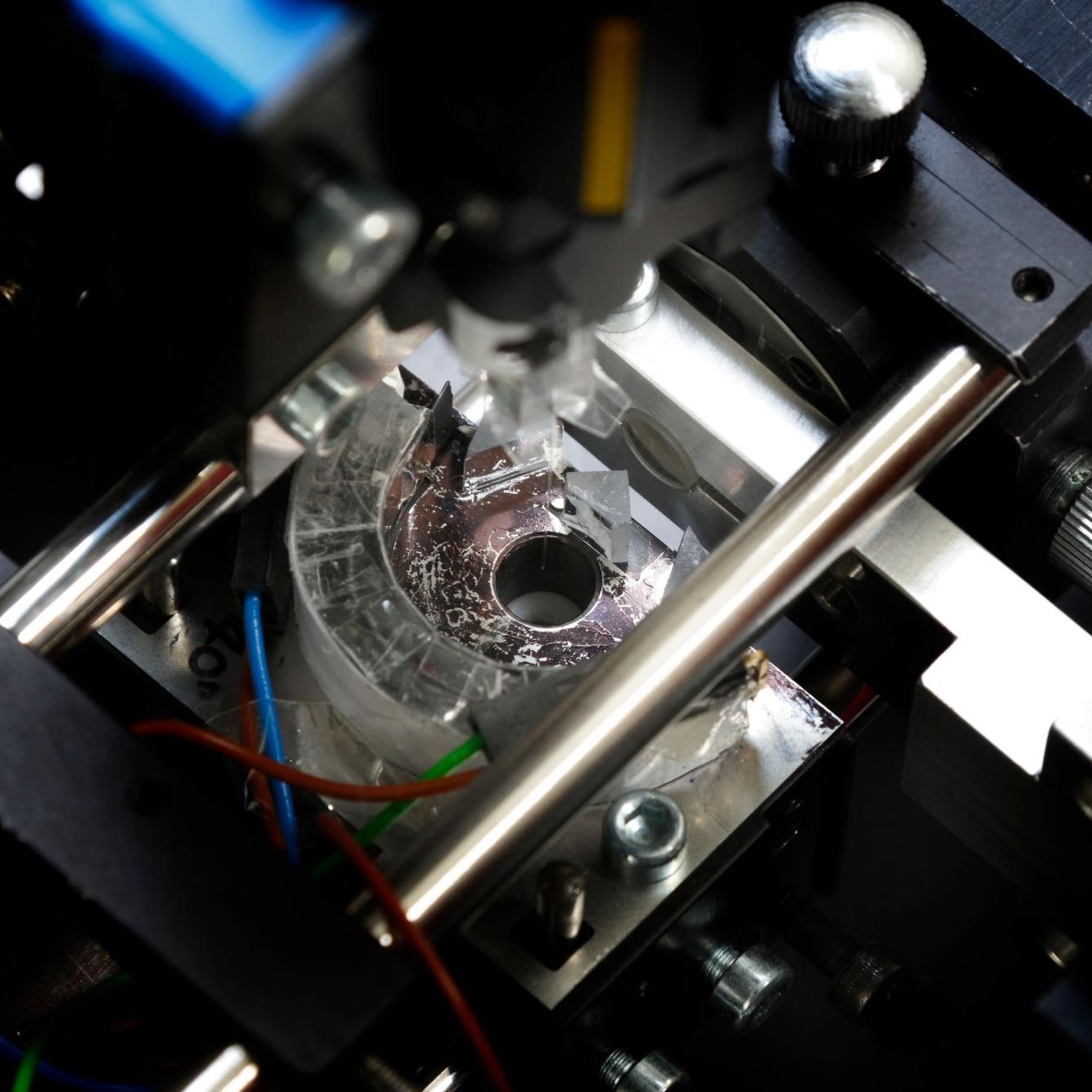

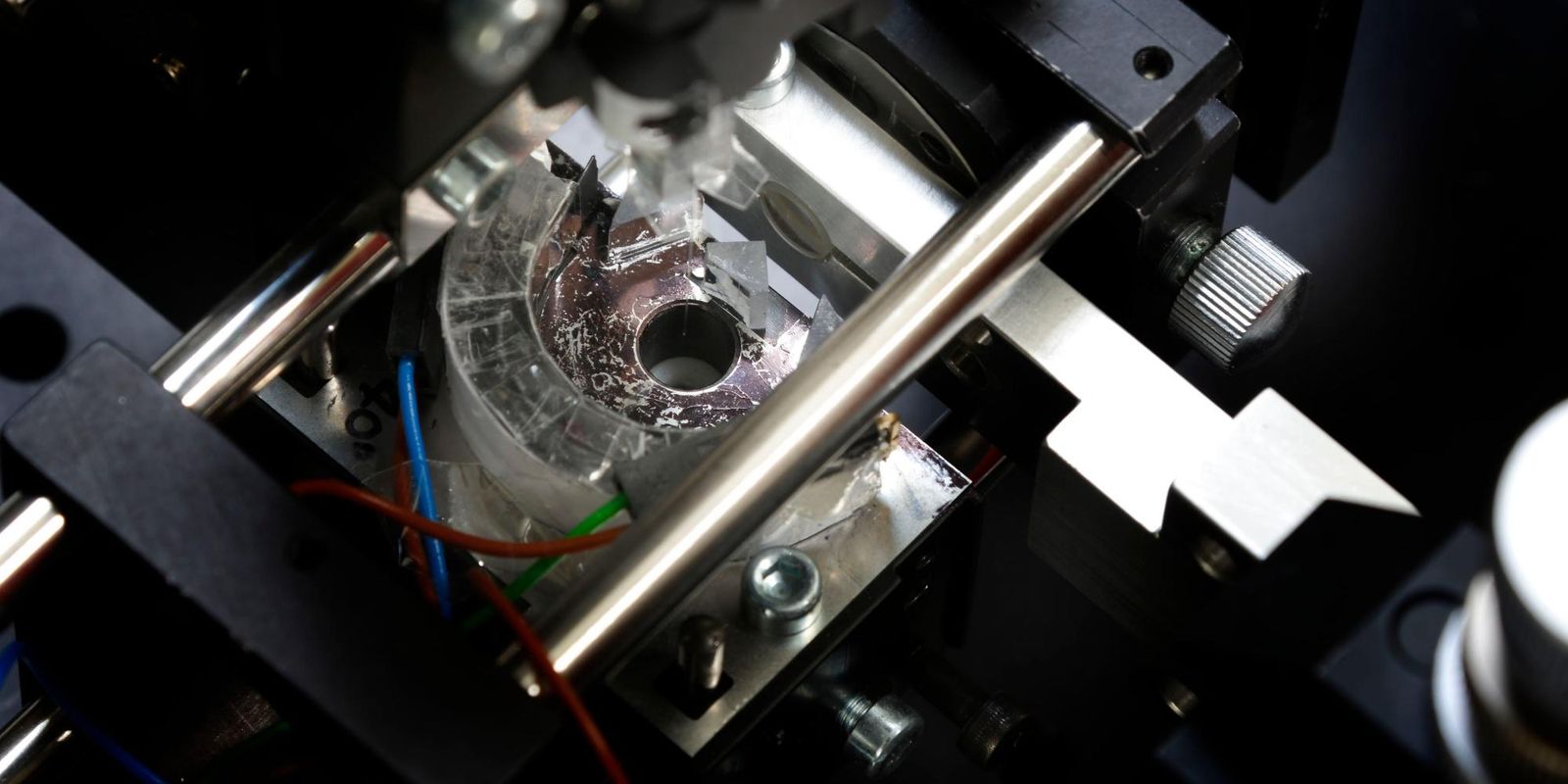

The integration of equipment into a functioning system is a typical Demcon feat. The actual printhead was produced by Canon Production Printing. All modules were brought together in a small space. Even a separate camera system for self-calibration was built into the system.

An important field of application of the metal jetting technology could be electronics manufacturing, for instance, to produce ‘vias’, the bridges between chips. Another possibility could be the production of (prototype) Micro Electro-Mechanical Systems (MEMs).

a hot challenge.

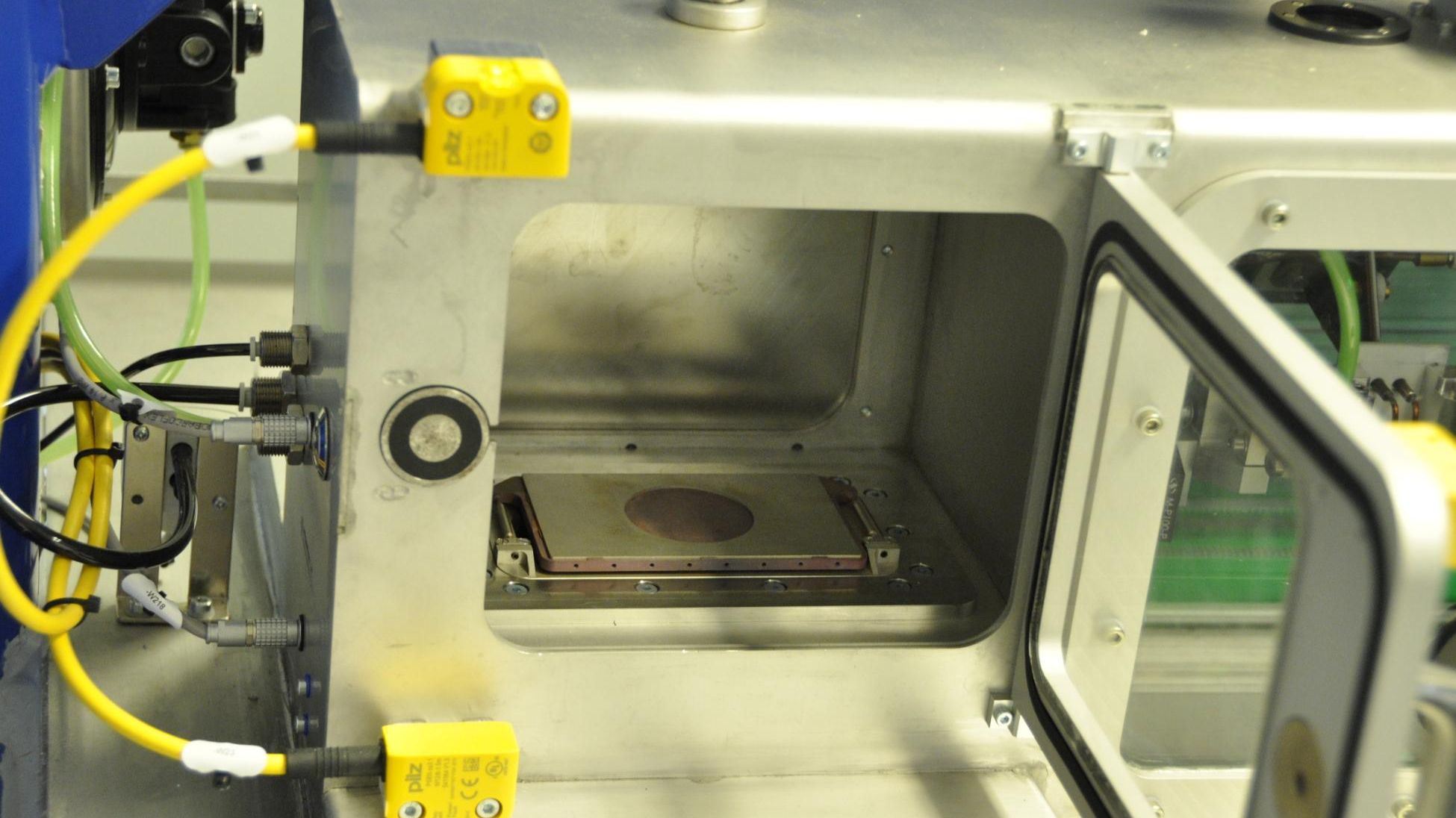

The biggest challenge of the project was the temperature control around the 1,800 ºC print head, placed at 10 cm above the 500 ºC substrate holder with vacuum clamp and very high quality heater element, located on a stage cooled down to room temperature.

This whole system had to function with 5 micrometer position accuracy. On top of that, this environment had to be made oxygen-free to prevent oxidation. This was created by a pure argon gas flow in a chamber in which the heart of the system was placed. The substrate holder was custom made from specialty materials to secure stability up to a temperature of 500 ºC. The fact that the stage underneath should remain at 20 ºC is telling about the cooling requirements.

"a silver logo."

The system was commissioned to the Additive Manufacturing and 3D Printing Research Group (3DPRG) at the University of Nottingham. The first object to be printed was a silver logo of the subsidy provider. Professor Richard Hague travelled to London to present it in person. I think that was a very stylish way to emphasise the project result.

more cases & tech insights.

Hemics HandScan: fast, painless and objective screening for rheumatoid arthritis

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more

Producing medical radio-isotopes with minimal nuclear waste

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more