highlights

• qualification of over 200 parameters

• mechanical interface matching the ASML machine

• seperate long-stroke/short-stroke testing

• real-time control in several degrees of freedom

more connectivity tests.

The PMQT4 is a fourth-generation Position Module Qualification Tool for a wafer positioning module of ASML’s NXT platform. The tool tests and qualifies a large number of properties and parameters. These range from connectivity (electric, pneumatic and water) to positioning precision and dynamic behavior, in the magnetic, electrical, mechanical, thermal and software (control) domains. We created a completely new design in which the number of connectivity tests was expanded, the reliability of the tool was increased further and the ergonomics (accessibility of the tool) were improved.

better usability design.

For accurate positioning over a wide range, the module contains separate stages for long-stroke and short-stroke movements. We have designed the PMQT4 to make it possible to test these long-stroke and short-stroke stages separately, to facilitate and accelerate the development process. We realized the PMQT4, just like other qualification tools, on a turnkey basis. Because the tool is deployed in production at ASML, it must be fast and simple to operate and have as little downtime as possible. To that end, we addressed usability in the design phase and provide for maintenance and service.

“we created an optimal fit between ASML’s module and our tool.”

We developed the PMQT4 as a kind of artificial machine around the position module to be tested. Based on our understanding of ASML’s hardware and operating systems, we designed interfaces to create an optimal fit between their module and our tool. In collaboration with their engineers, we conducted a failure mode and effects analysis, to determine the required tests and parameter qualifications. All in all, our qualification tool track record for the NXT platform helped us to qualify for ASML’s next platform generations, NXE and EXE.

more cases & tech insights.

Hot head on a cool stage

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

Hemics HandScan: fast, painless and objective screening for rheumatoid arthritis

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

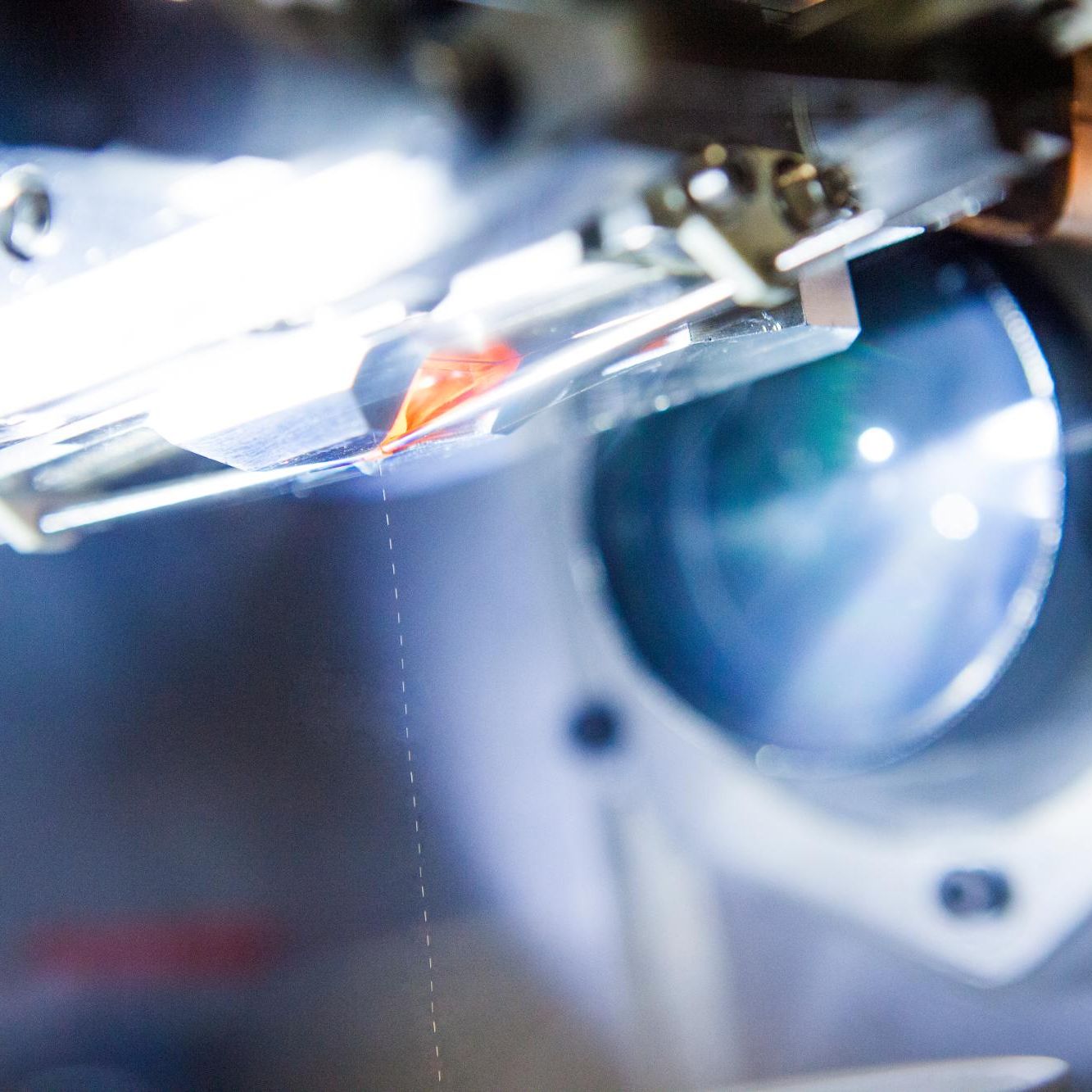

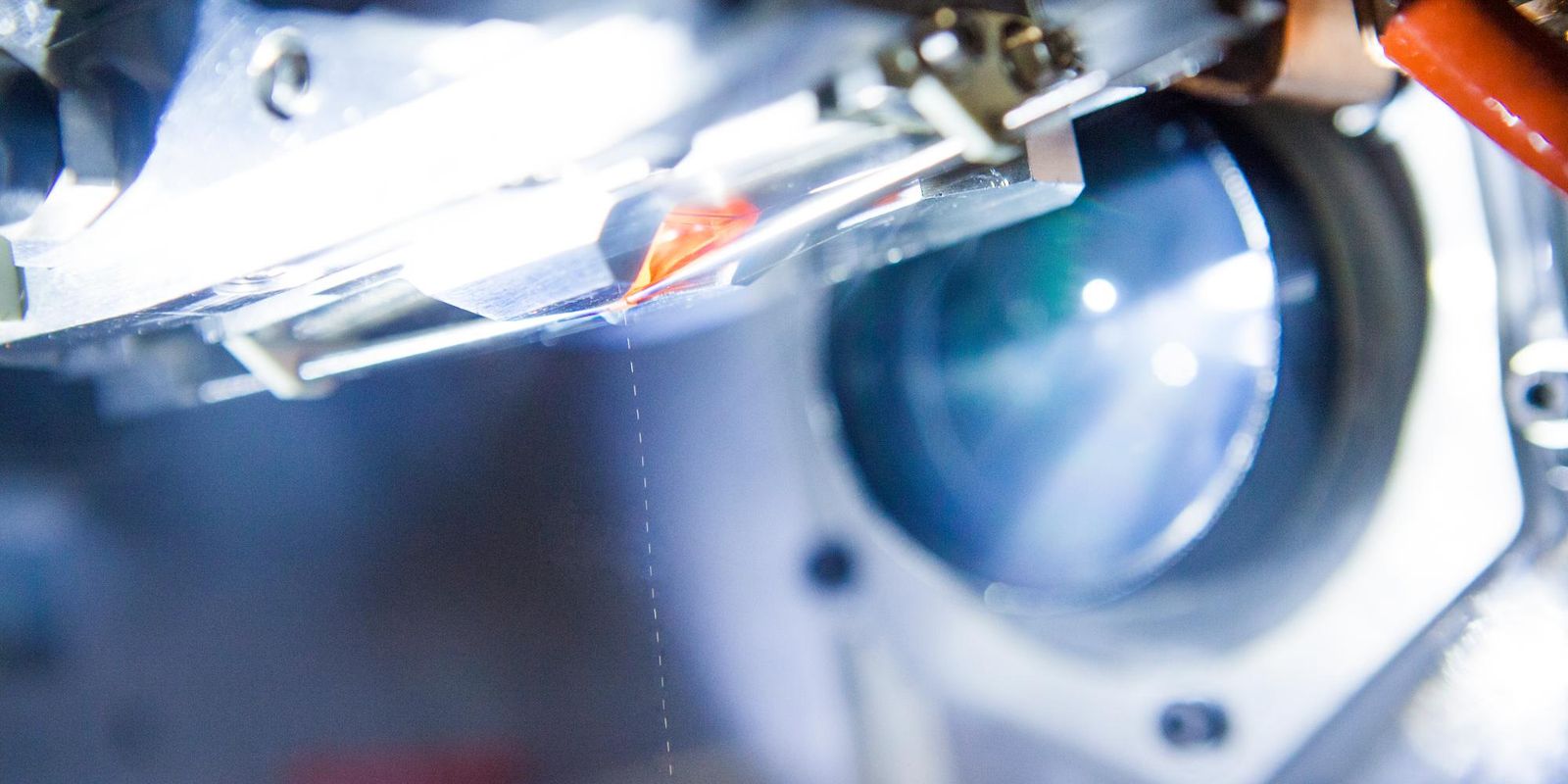

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

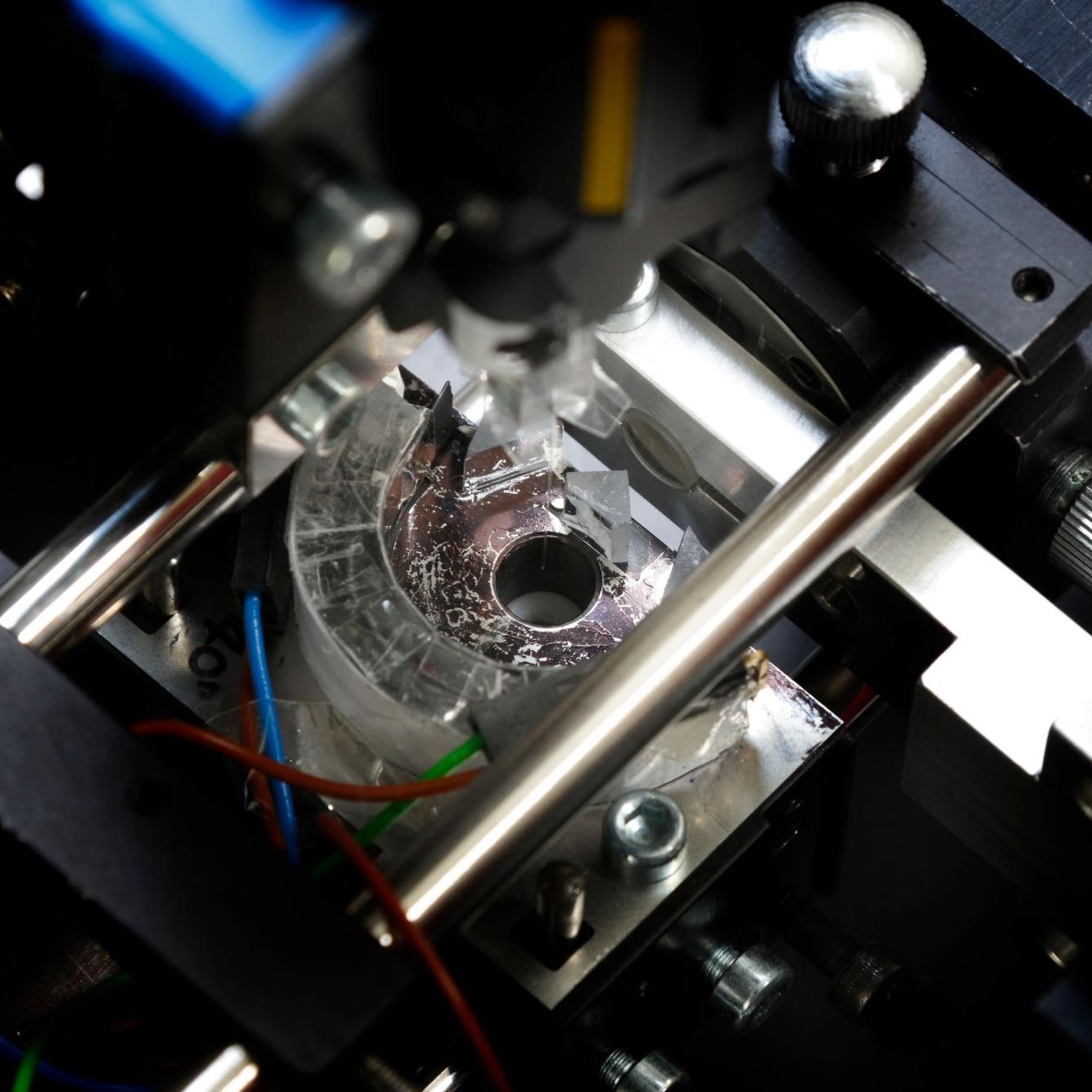

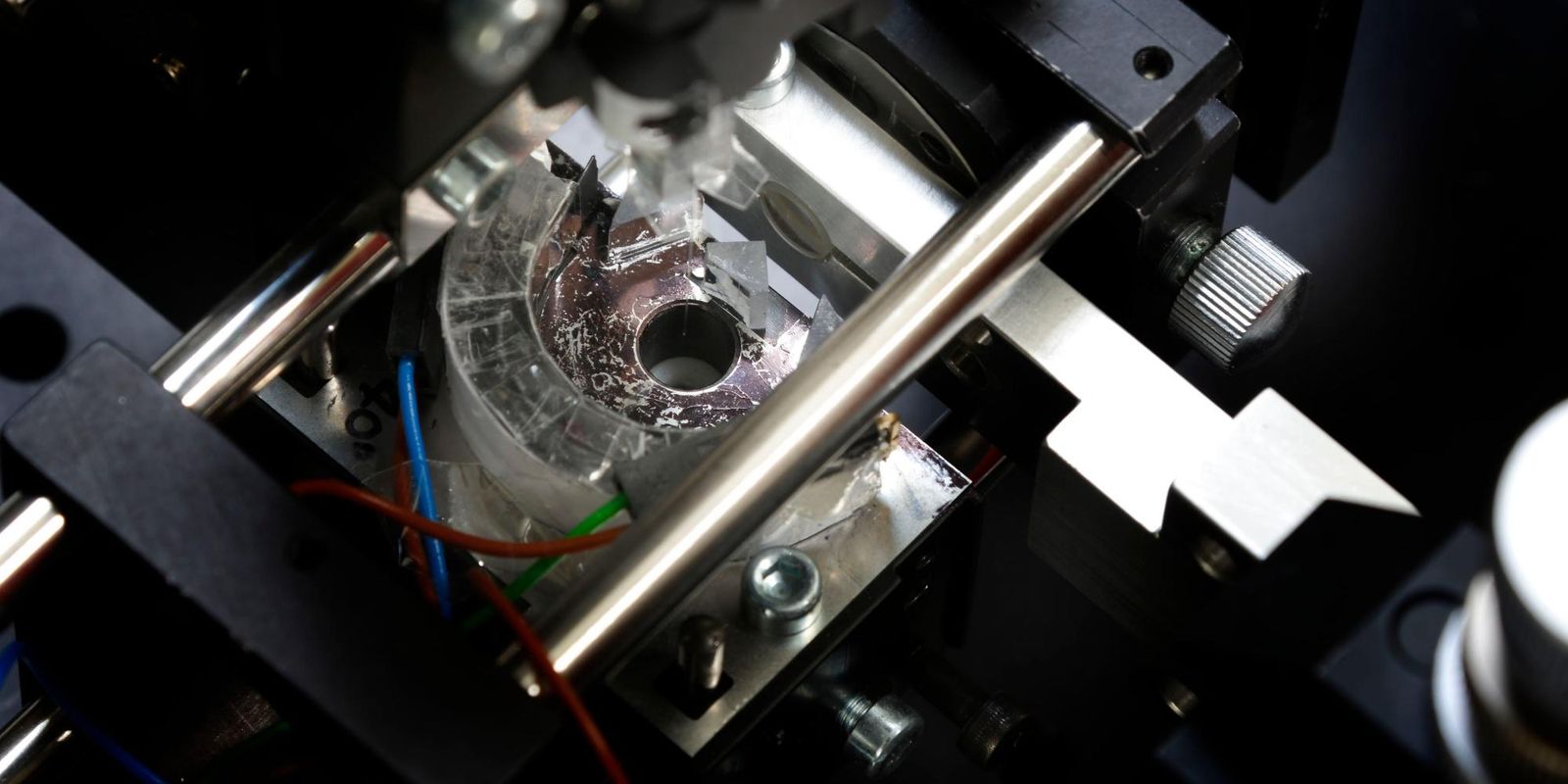

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more