highlights

• no impact on image thanks to design and materials choices

• image integration

• clever placement of actuators and transmission

• engineered within the limited available space

how does a needle replacement robot work?

The starting point for developing the needle replacement robot was to retain the current workflow as closely as possible, and only to automate the steps critical for the speed and result (‘first time right’) of the procedure. The critical step is determining the angle at which the needle enters the body.

As a result, we developed a system comprising a head with a needle-guidance mechanism and an arm which secures the head in relation to the operating table with one press of a button. The head can be positioned around the patient manually. Once the system has been positioned around the patient, it accompanies the patient into the CT scanner to determine the position of the patient’s tumor in relation to the head. When determined, the system automatically steers the needle-guidance mechanism to assign it the required direction. The needle is then clamped into the guidance mechanism and inserted into the body by the doctor himself.

what were our challenges?

Firstly, the system architecture based on the current medical workflow was a challenge. It needed to minimize the barriers to being used by the doctor, both literally and figuratively. A second challenge was the design factor. The entire system, including arm and head, needed to fit in the (tight) space between the patient and the CT scanner’s ring.

However, the biggest hurdle was CT compatibility. The bulk of the system would enter the scanner’s X-ray field but should not disrupt the imaging. That meant that the usual materials like steel, copper and titanium were not an option. We worked with several suppliers including Ceratec (ceramics) and Futura Composites to develop alternatives. Varieties of materials were used in the components, such as composites (for rigid construction parts and flexible elements), ceramics (for highly stressed precision parts and ball bearings), Dyneema fibers (for rotating cable drives), carbon nanotubes (for power wires and switches) and plastic optic fibers (to read out encoder positions remotely).

These solutions imparted high rigidity to the construction, minimizing any transmission play. The result is a system which can guide the needle correctly and precisely, with a margin of error of less than 2 mm at a depth of 25 cm. This means the patient suffers only minimal tissue damage, the medical team can complete the procedure more quickly (and thus more economically), and the doctor remains ‘in control’.

"just the right amount of support."

We developed the needle placement system in close collaboration with medical specialists from the Erasmus Medical Center Rotterdam and the University Medical Center Groningen (UMCG). Besides development, we also conducted the clinical study to validate the system. The study included 28 patients at the University Medical Center Groningen (UMCG). The robot-supported method proved to have clear advantages over the manual approach, one prominent advantage being the milder impact on the patient.

more cases & tech insights.

ice cold stability.

In life sciences research, studying cryogenic samples of proteins, viruses and bacteria becomes more and more popular to answer these questions. With Kryoz, Demcon has a cryogenic micro cooler for integration in the electronic microscope on the market.

Read more

reviving instant photography.

A Polaroid film cartridge production line in Enschede was revived from 2008 onward. Demcon Industrial Systems supports this process with a retrofit process module and works at improving the ultra-fast production line’s reliability. Both the line and the products are now better than ever.

Read more

producing medical radio-isotopes with minimal nuclear waste.

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more

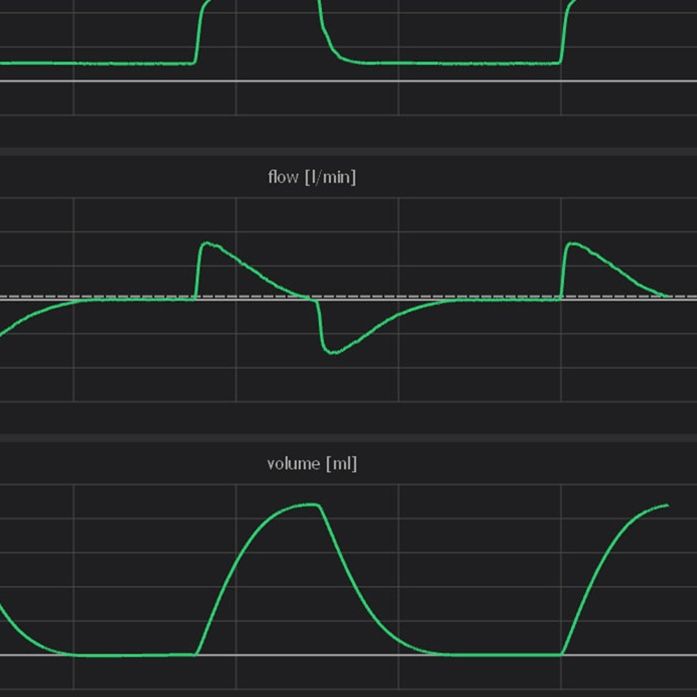

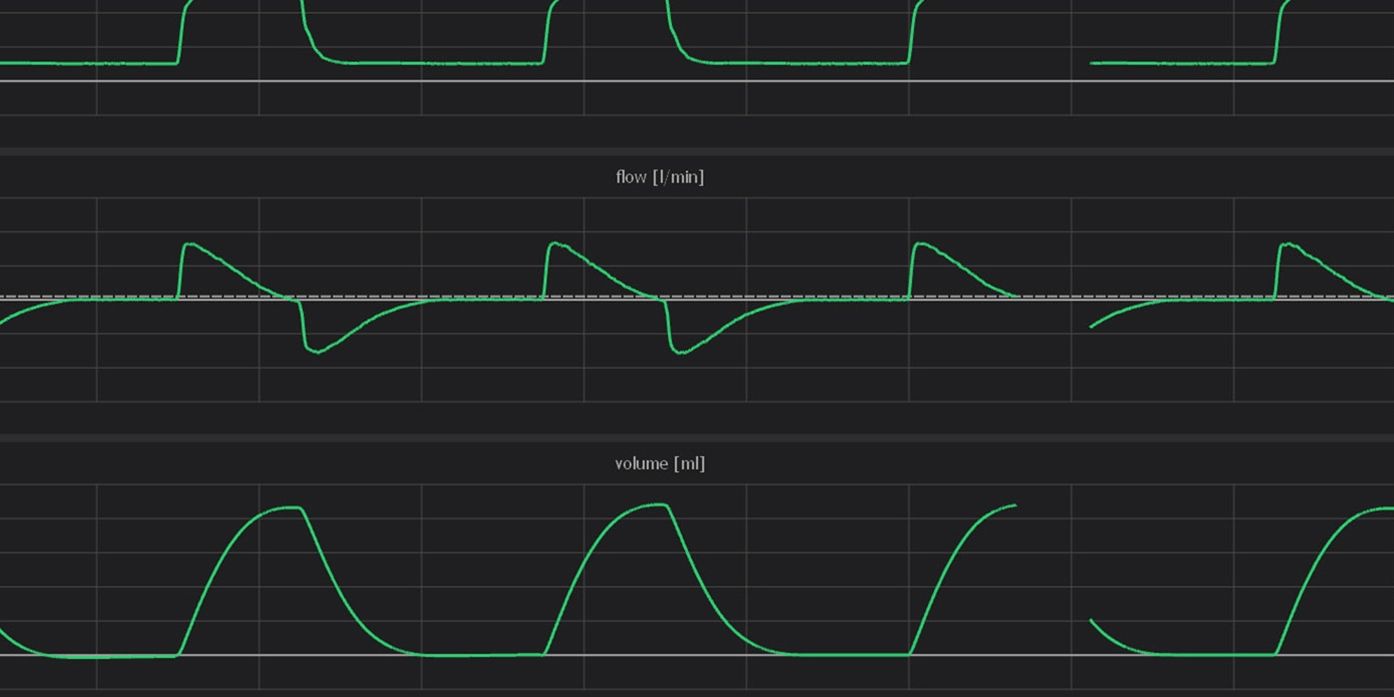

use cases in machine learning for time series.

It is essential that the ventilator support is synchronized (in time) with the patient’s spontaneous breaths. A mismatch in this timing is referred to as Patient-Ventilator Asynchrony (PVA). To improve the patient’s comfort and recovery this PVA must be prevented. A key step in this process is the detection and classification of PVA.

Read more