highlights

• millisecond range accuracy

• high reliability, low maintenance

• retrofit process module

• handling 180 films per minute

multi-disciplinary approach.

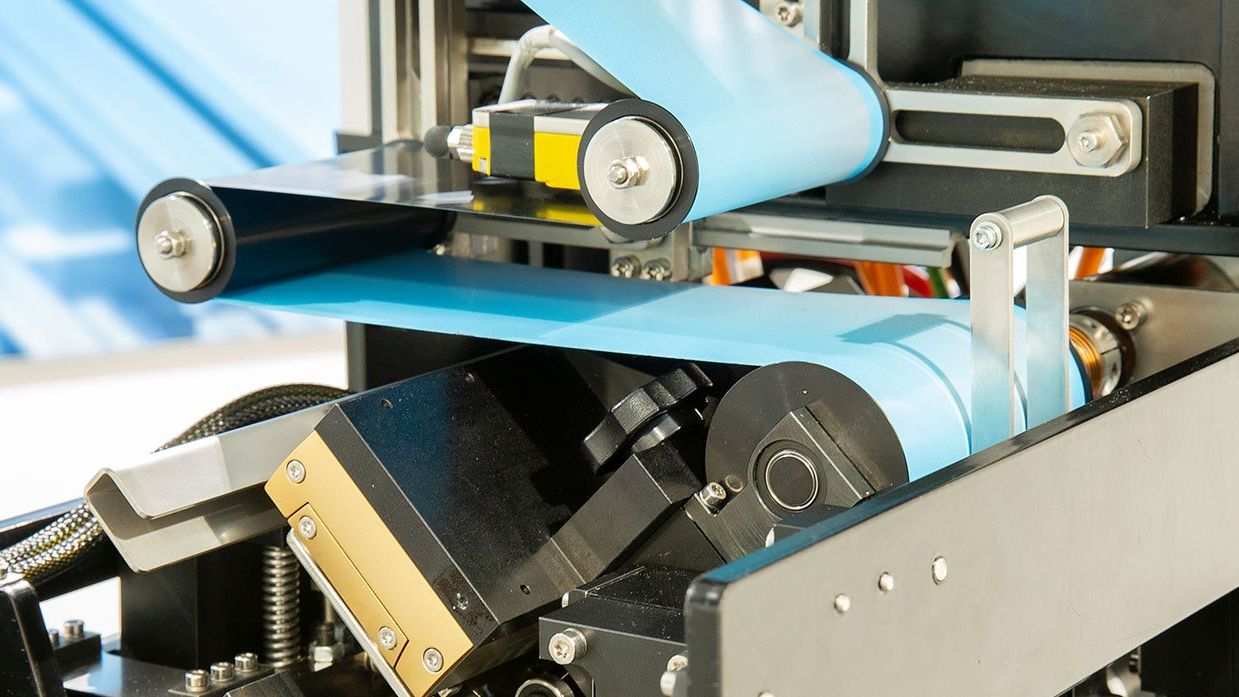

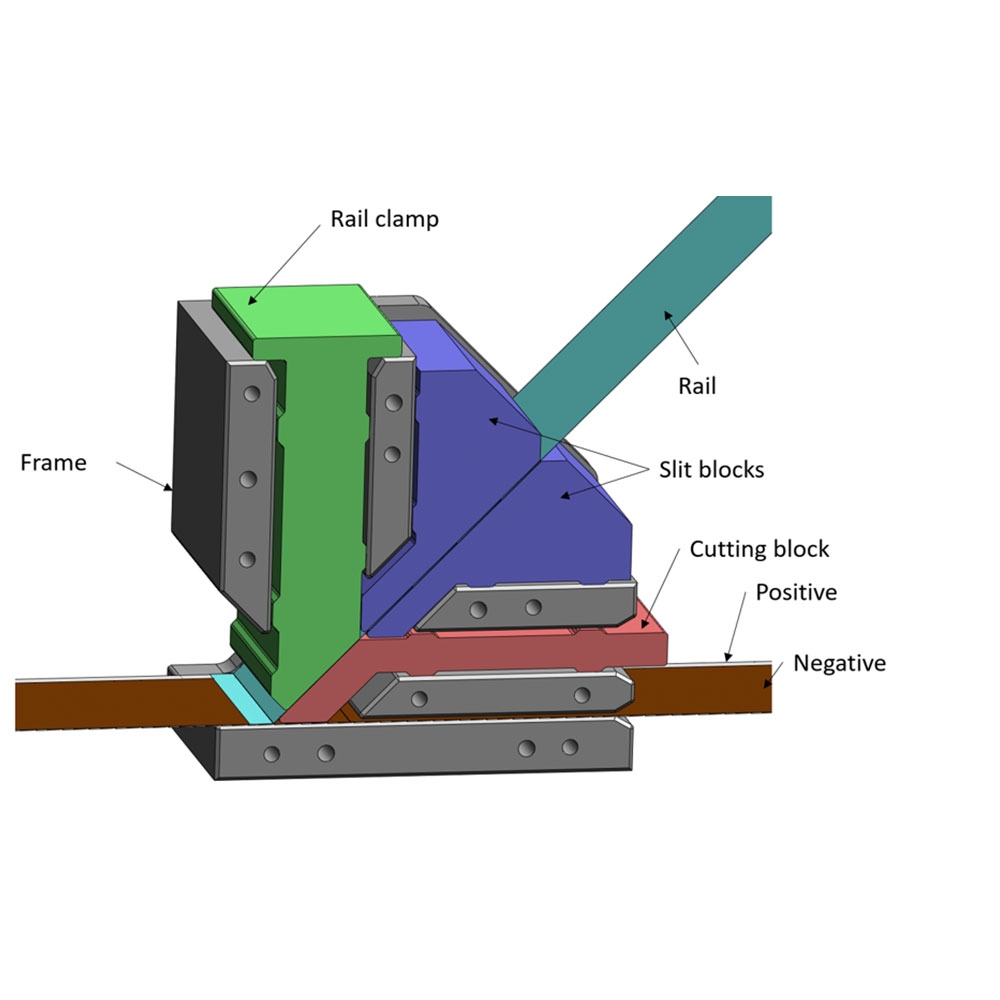

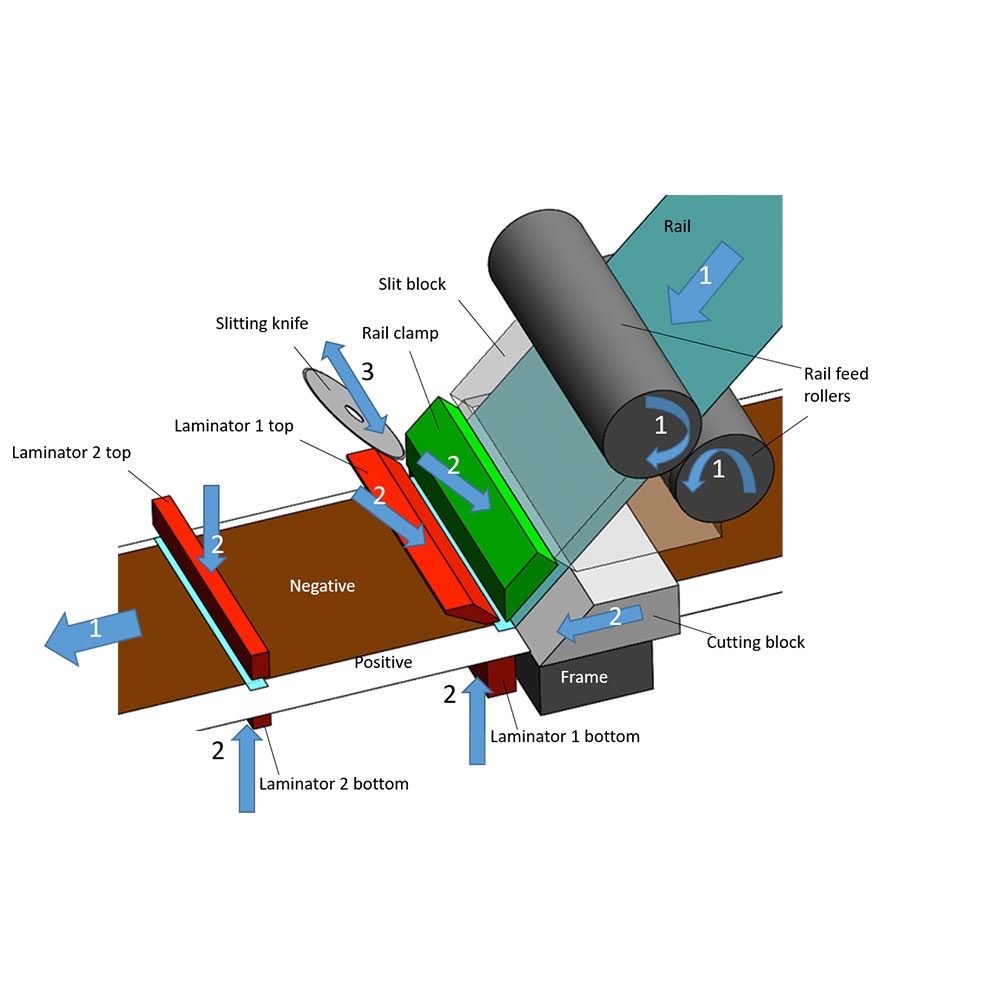

In the Polaroid instant camera and film technology, chemistry and materials are combined ingeniously. Take for instance the complex film production in Enschede. An important step in the process is cutting the film into so-called ‘rails’, narrow strips that are laminated onto the photosensitive material, thus connecting the negative to the underlying positive. The rails serve to guard the distance during the development process in the camera, seeing to it that a roll can apply the developer liquid in the right layer thickness to the negative.

Since the production line was revived, it turned out that the existing process had difficulty with cutting, laminating, and handling the present, 30-50 μm thin-film material of the rail. Demcon Industrial Systems was asked to develop a robust and reliable new solution for cutting and laminating. Preconditions: it should be able to handle 180 films per minute and be highly flexible in handling different film types and sizes.

high reliability, low maintenance.

Out of various options, a circular knife promised the best cutting results. To address possible wear issues, extensive tool lifetime tests were carried out. These proved that even after a million cycles there is still a clean cut. The system is designed for low maintenance. The use of leaf springs and extremely reliable bearings leads to a whopping 22 million cycles of maintenance-free operation. The eventual exchange of wear-sensitive tools leads to minimal downtime.

The laminating process was also revised. The ‘hot block’ technology remained, but with the use of a copper alloy instead of steel for better heat transfer. To optimize the process critical process timing, the mechanical control system was replaced by a mechatronic camming system seeing to millisecond range accuracy in servomotor control.

"success for a large multidisciplinary development team."

For this project, we were able to deploy our expertise in system architecture, physical-chemical processes, mechatronics, system integration, and industrialization. With this, we did our bit to help realize the impossible: to revive a technology deemed obsolete. The fully operational new module has already been used to train the Polaroid staff. It now awaits integration during the next maintenance window, so that it can henceforth boost the overall line reliability.

more cases & tech insights.

ice cold stability.

In life sciences research, studying cryogenic samples of proteins, viruses and bacteria becomes more and more popular to answer these questions. With Kryoz, Demcon has a cryogenic micro cooler for integration in the electronic microscope on the market.

Read more

the right angle.

To diagnose liver cancer, a physician takes a biopsy by accurately inserting a needle in the tumor. However, it is hard to reach the right spot manually based on the CT image. To overcome this, a needle placement robot helps the medical specialist find exactly the right angle to place the needle the first time right.

Read more

producing medical radio-isotopes with minimal nuclear waste.

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more

use cases in machine learning for time series.

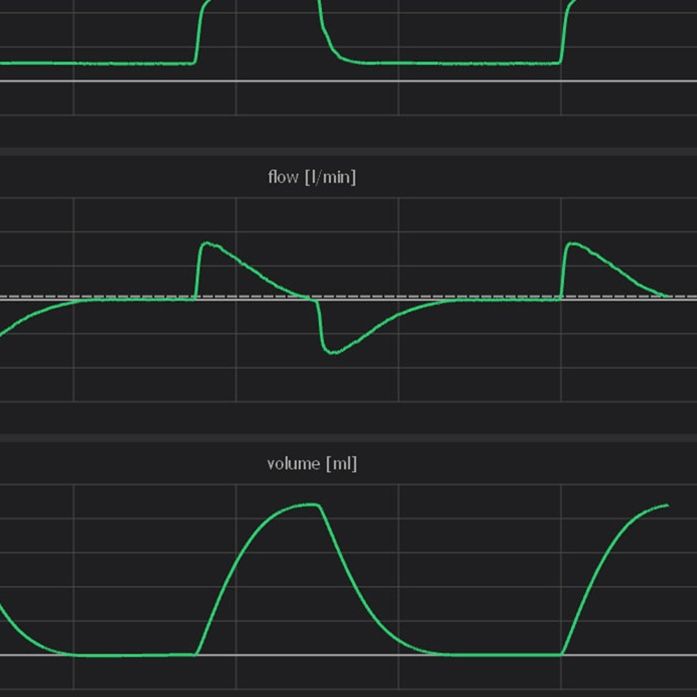

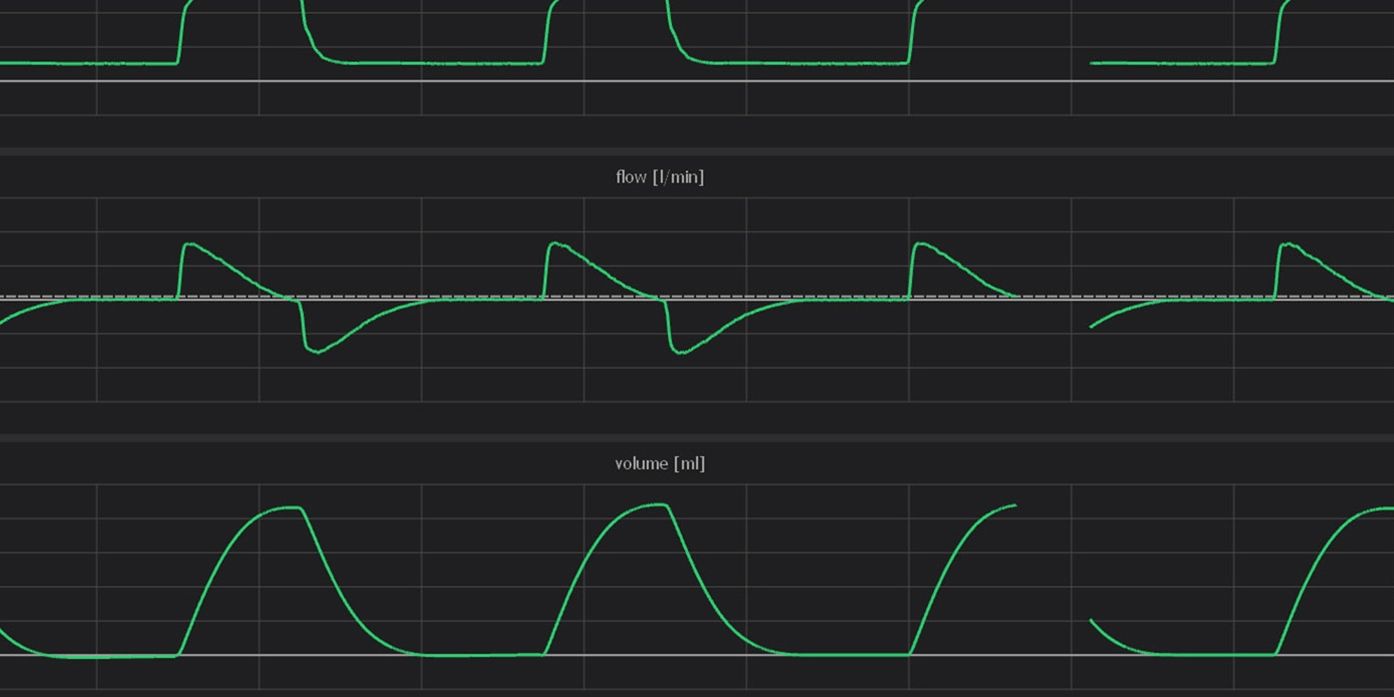

It is essential that the ventilator support is synchronized (in time) with the patient’s spontaneous breaths. A mismatch in this timing is referred to as Patient-Ventilator Asynchrony (PVA). To improve the patient’s comfort and recovery this PVA must be prevented. A key step in this process is the detection and classification of PVA.

Read more