highlights

• 1 to 2 nm accuracy in static measurements

• 10 nm accuracy in dynamic measurements

• 95 engineers worked on a successful redesign

complete makeover.

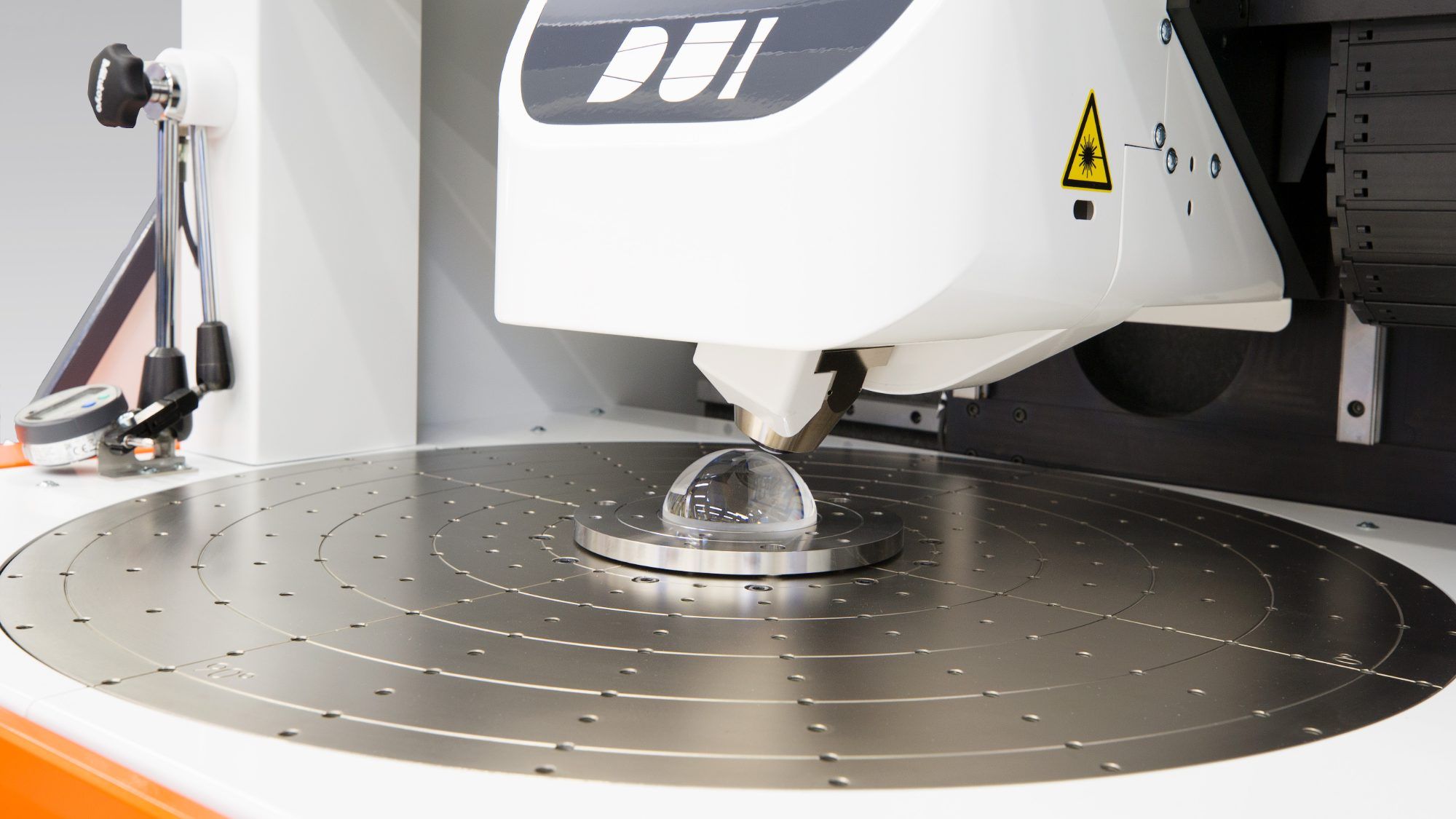

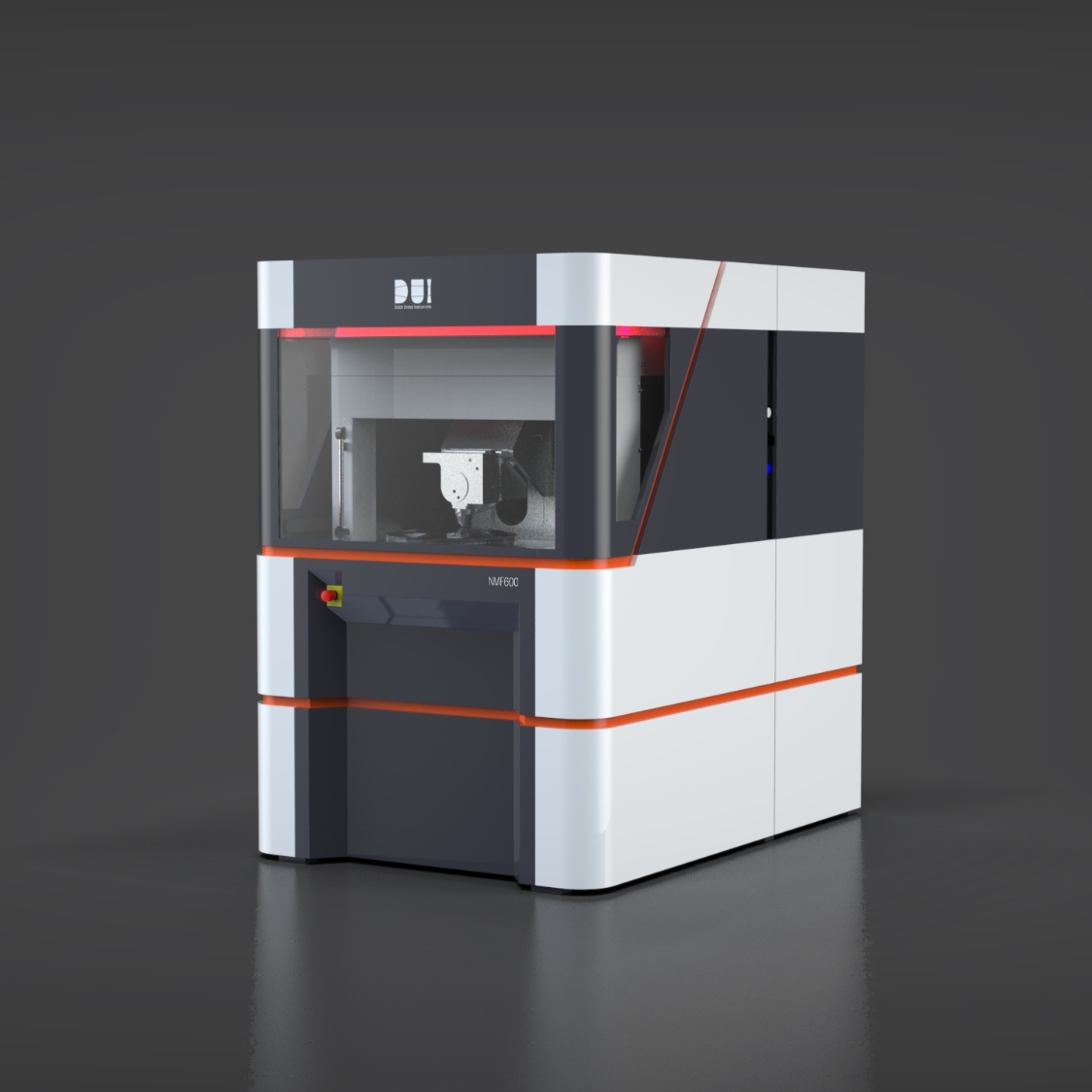

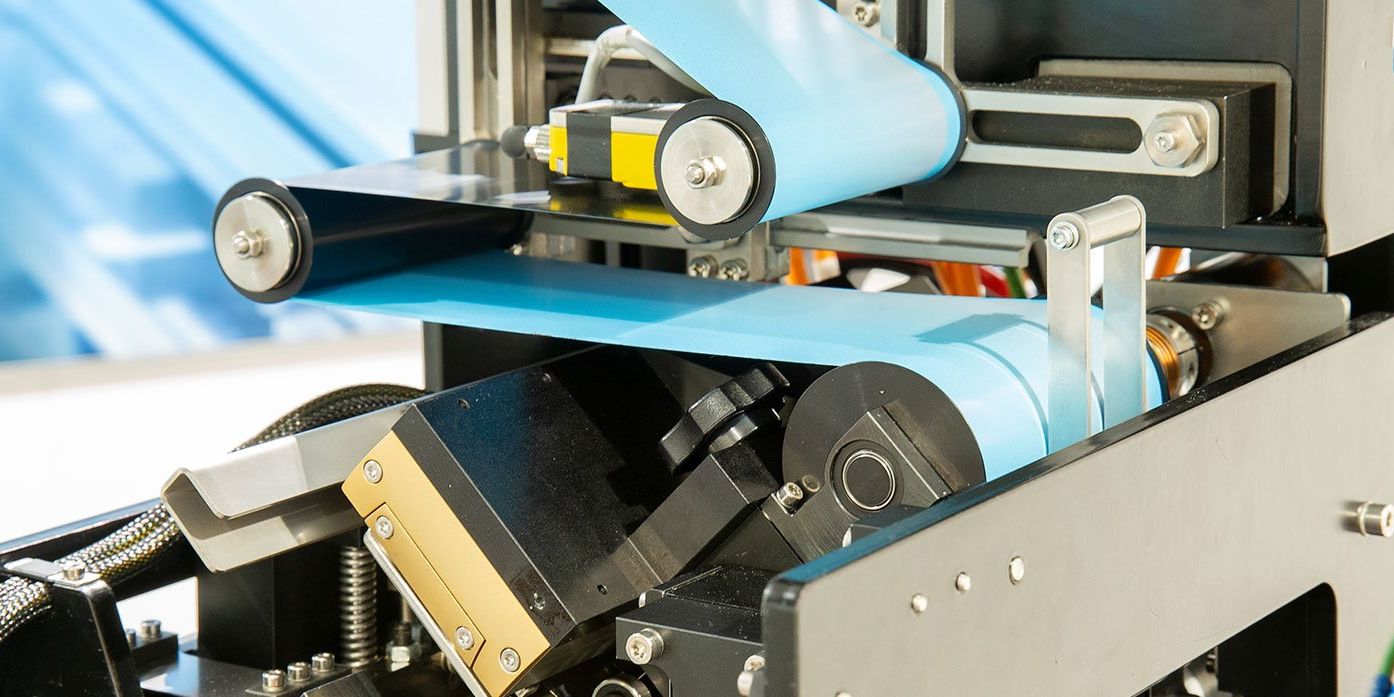

There are systems on the market that can measure freeform lenses with 40 to 50 nm accuracy, where 8 to 10 nm accuracy from all angles is required. TNO and TU Eindhoven developed the Nanomefos platform that was capable of that. Demcon took this as the starting point to develop a completely made-over commercial system for fast, contactless and highly accurate metrology. The team was lucky to have Rens Henselmans on board, who was involved in the initial Nanomefos development.

accuracy to the max.

Accuracy and stability are key to Nanomefos. A number of clever tricks were applied to attain 1 to 2 nm accuracy in static and 10 nm in dynamic measurements.

One of these is to first quickly measure over the axes of the object. Subsequently, the object is read like a compact disc for ten to fifteen minutes. This time-lapse typically leads to a considerable drift, that can be corrected thanks to the first quick measurement.

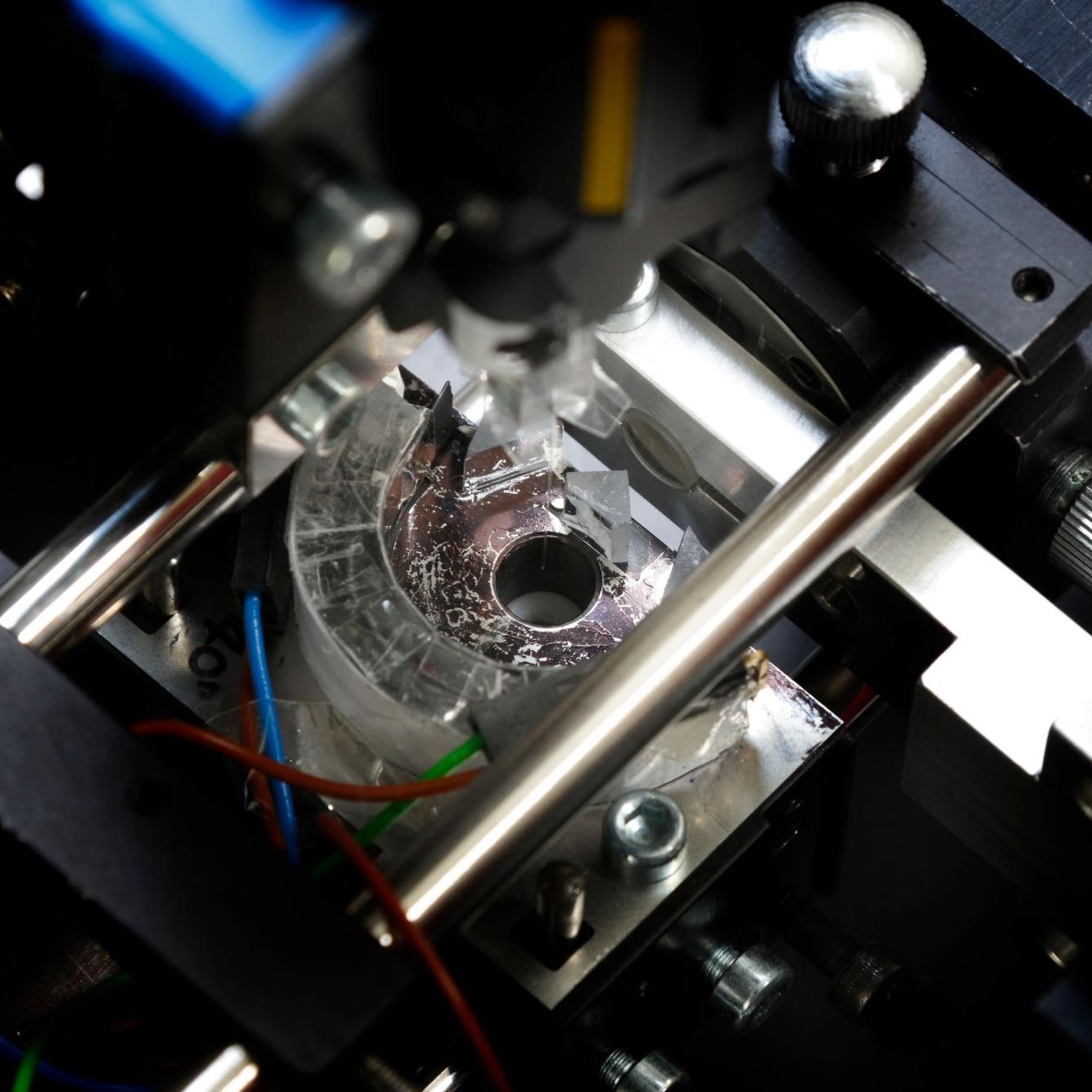

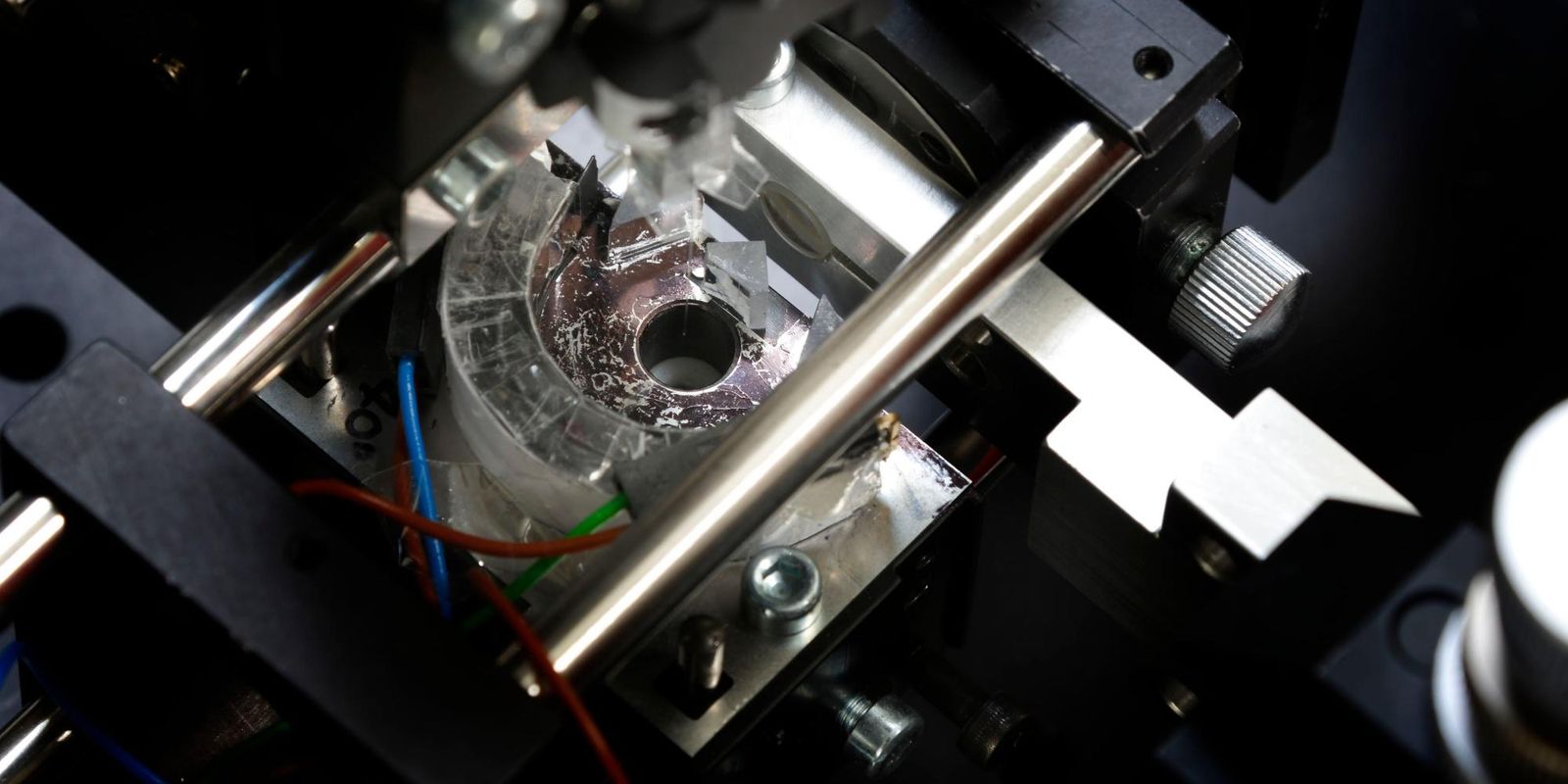

In order to measure accurately, it is also vital to exactly know the position of the probe relative to the object. Silicon carbide beams guarantee basic mechanical stability. Interferometry is used to define the position of the probe and object in space. Both vary hundreds of nanometers during measurement, but correctional calculations compensate for that.

"success for a large multidisciplinary development team."

With a team of 95 engineers, we managed to successfully redesign a prototype into a commercial product. The team covered software, mechanics, electronics, optics, data analysis and data processing competencies alongside specializations within these fields. So far, DUI built three of these highly specialized systems and four more are being built now. That is quite an accomplishment and is very satisfactory.

more cases & tech insights.

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

Producing medical radio-isotopes with minimal nuclear waste

Radio-isotopes are widely used for medical diagnostics and treatment, predominantly in cancer care. The current production method has only a 2% yield of the isotope wanted. The rest is mostly nuclear waste. Demcon helps to produce it with minimal nuclear waste.

Read more

The right angle

To diagnose liver cancer, a physician takes a biopsy by accurately inserting a needle in the tumor. However, it is hard to reach the right spot manually based on the CT image. To overcome this, a needle placement robot helps the medical specialist find exactly the right angle to place the needle the first time right.

Read more

Reviving instant photography

A Polaroid film cartridge production line in Enschede was revived from 2008 onward. Demcon Industrial Systems supports this process with a retrofit process module and works at improving the ultra-fast production line’s reliability. Both the line and the products are now better than ever.

Read more