Key advantages

This approach poses several advantages over conventional Tuned Mass Dampers:

- Adds virtually no mass or volume

- Remains tunable

- Integrates easily within flexure mechanisms

Moreover, this active approach allows suppression of a particular frequency without deteriorating others, which is difficult to achieve with viscous or viscoelastic dampers.

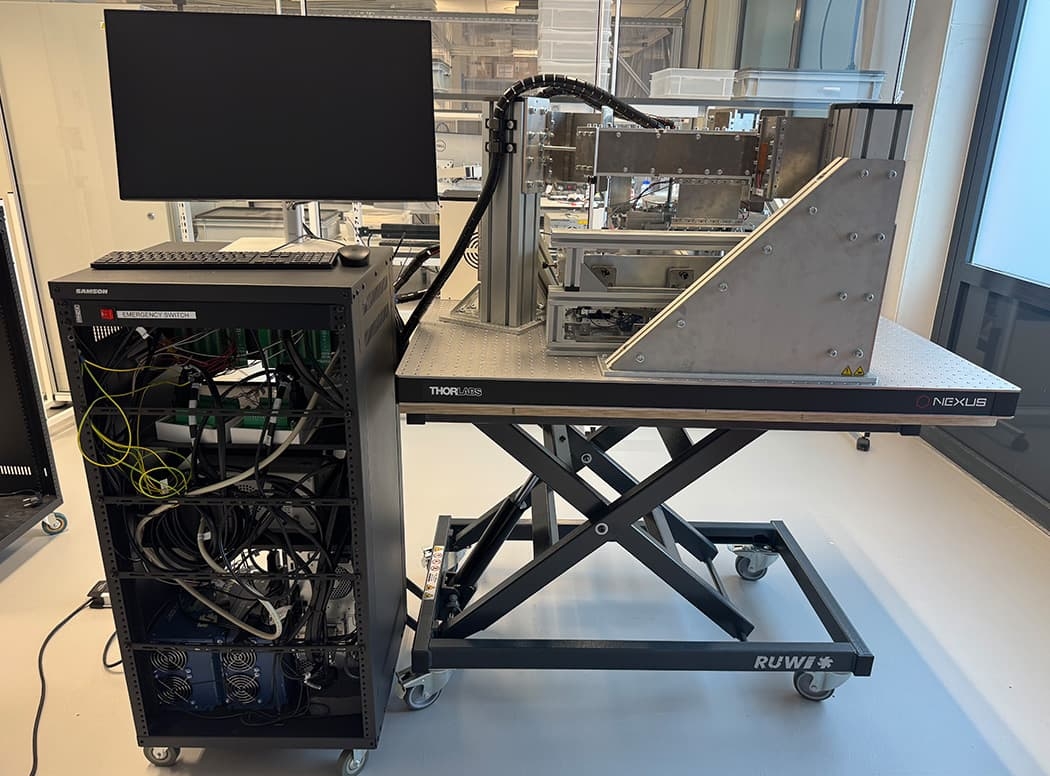

The demonstrator setup shows the technique on a 6 degree-of-freedom (DoF) system. Piezoelectric patches are used to suppress the nominal eigenfrequency of a newly designed six-DoF flexure-based vibration isolation system.

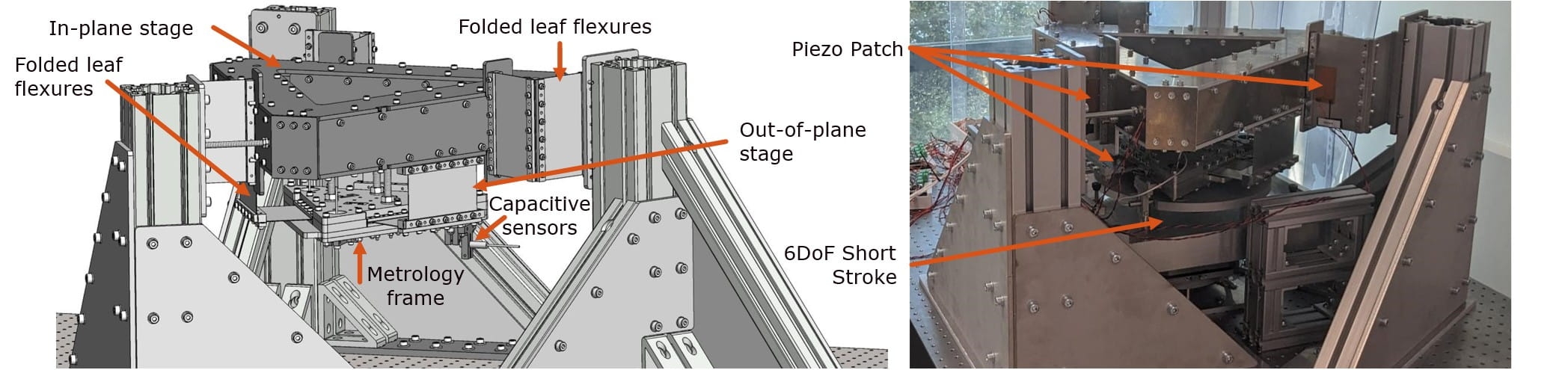

Figure 1 shows the designed system, consisting of two stages with three folded leaf flexures each. The first stage releases in-plane modes, while the second stage releases out-of-plane modes, together freeing all six DoF with a suspension frequency between 10 and 22 Hz. The six-folded leaf flexures have an integrated piezoelectric sensor and actuator in the form of a bimorph flexure, see Figure 2.

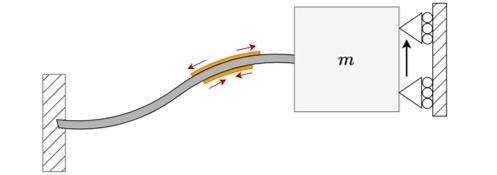

Figure 2 shows a schematic of a piezoelectric bimorph. Applying a voltage over the lower patch causes it to contract, bending the leaf flexure and moving mass m upwards. This stretches the top patch, resulting in an output voltage, allowing it to be used as a sensor detecting the movement.

design approach.

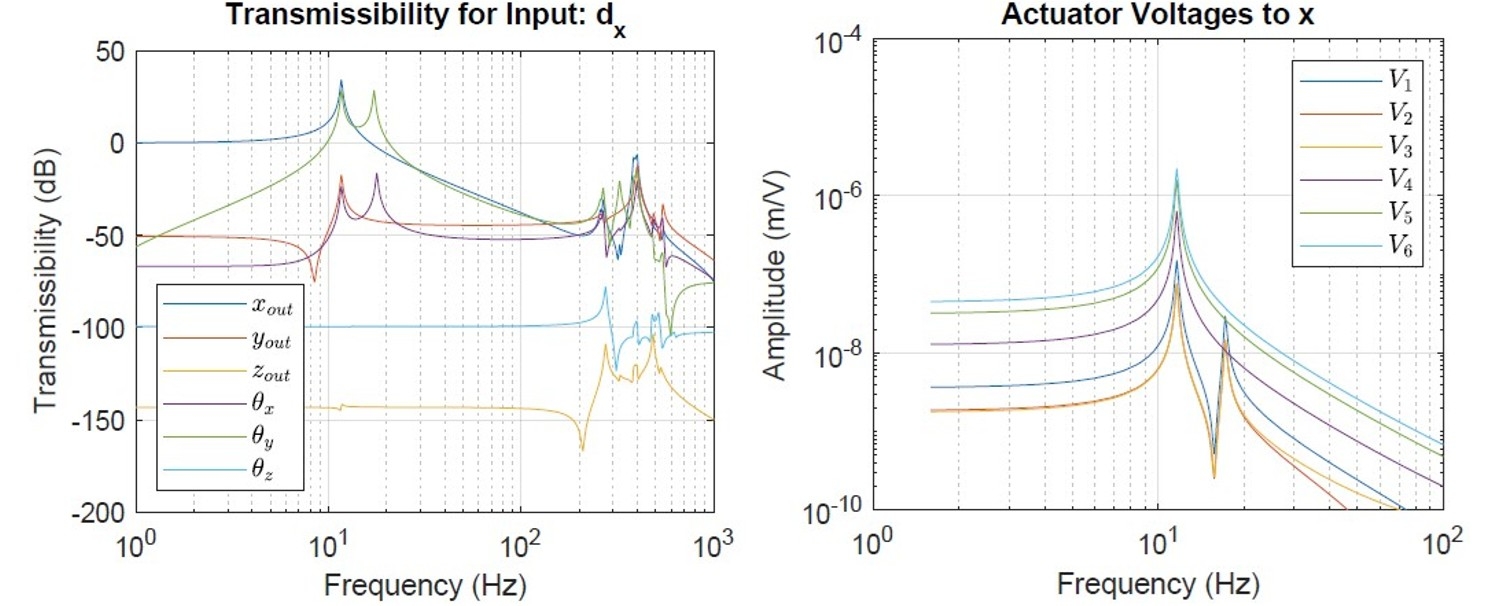

Key to the design's success was the utilization of the piezoelectric extension to the multibody software SPACAR [3], allowing for rapid design iterations and concept selection. Example results are shown in Figure 3. SPACAR was employed for two main purposes. First, it analyzed the vibration transmissibility from the floor to the metrology frame, indicating the nominal suspension modes and parasitic resonances. Second, it indicated the coupling from piezoelectric patch voltage to metrology frame movements, ensuring that the patches were able to suppress the nominal modes.

Transmissibility results were validated using conventional Finite Element Analysis. After building, system identification and structured parameter estimation helped in determining the actual mode shapes. This identification largely aligned with the SPACAR predictions, as shown in Table 1.

Table 1. Resonance mode frequencies as predicted by SPACAR, validated through Finite Element Analysis (FEA), and measured on the setup. These six modes are nominal suspension modes; higher modes are parasitic.

|

Frequencies [Hz] |

Mode 1 |

Mode 2 |

Mode 3 |

Mode 4 |

Mode 5 |

Mode 6 |

|

SPACAR |

11.6 |

11.6 |

13.1 |

14.3 |

18.5 |

19.1 |

|

FEA |

10.3 |

10.3 |

12.2 |

13.3 |

18.9 |

18.9 |

|

Measured |

12.3 |

12.5 |

14.2 |

15.2 |

20.4 |

21.0 |

Modal decoupling was used to achieve a sufficiently decoupled system up to 25 Hz, indicated by the Relative Gain Array (RGA) being below 0.1 for those frequencies. This permitted a decoupled control approach for the six nominal suspension frequencies. A Positive Position Feedback (PPF) controller was tuned for each nominal mode, using H2-optimal tuning.

Figure 4. This mode is defined by -396x -478y. The input spectrum consists of white noise generated by the Short Stroke actuators, with the Short Stroke clamped in position. The parasitic modes observed between 60 and 197 Hz are caused by the clamping of the Short Stroke, making them results of the measurement method rather than internal modes [2].

![Figure 4. Left: Normalized measured impulse responses for Modeshape 1, scaling the maximum amplitude to 1. Right: Normalized measured Power-Spectral-Density (PSD) in [1/Hz] for Modeshape 1.](/.img/animated_true&w_2400&f_jpeg&q_100/dam/hightechsystems/public/showcases/Piezoelectric-damping-of-a-6-DoF-vibration-isolation-frame/Left-Normalized-measured-impulse-responses.-Right-Normalized-measured-Power-Spectral-Density.jpg)

results & conclusion.

The approach significantly increased modal damping from 0.4%-1.1% to 9%-13% [2]. Figure 4 shows the time and frequency domain improvements for one of the six mode shapes, with piezoelectric control damping the 13Hz resonance mode.

In conclusion, this work supports and highlights the potential of implementing piezoelectric damping within industrial applications. It is demonstrated that, with the current tools available, integration of piezoelectric patches can yield a substantial increase in modal damping, with values up to 13% being achieved. The comprehensive approach, from system design to experimental validation, provides a robust framework for future industrial applications.

solve challenges for and with you

We believe in the power of partnerships. So, to deliver as promised, we combine expertise, experience, and domain knowledge to create a winning team. Working side-by-side, creating shared value.

more cases & tech insights.

Hot head on a cool stage

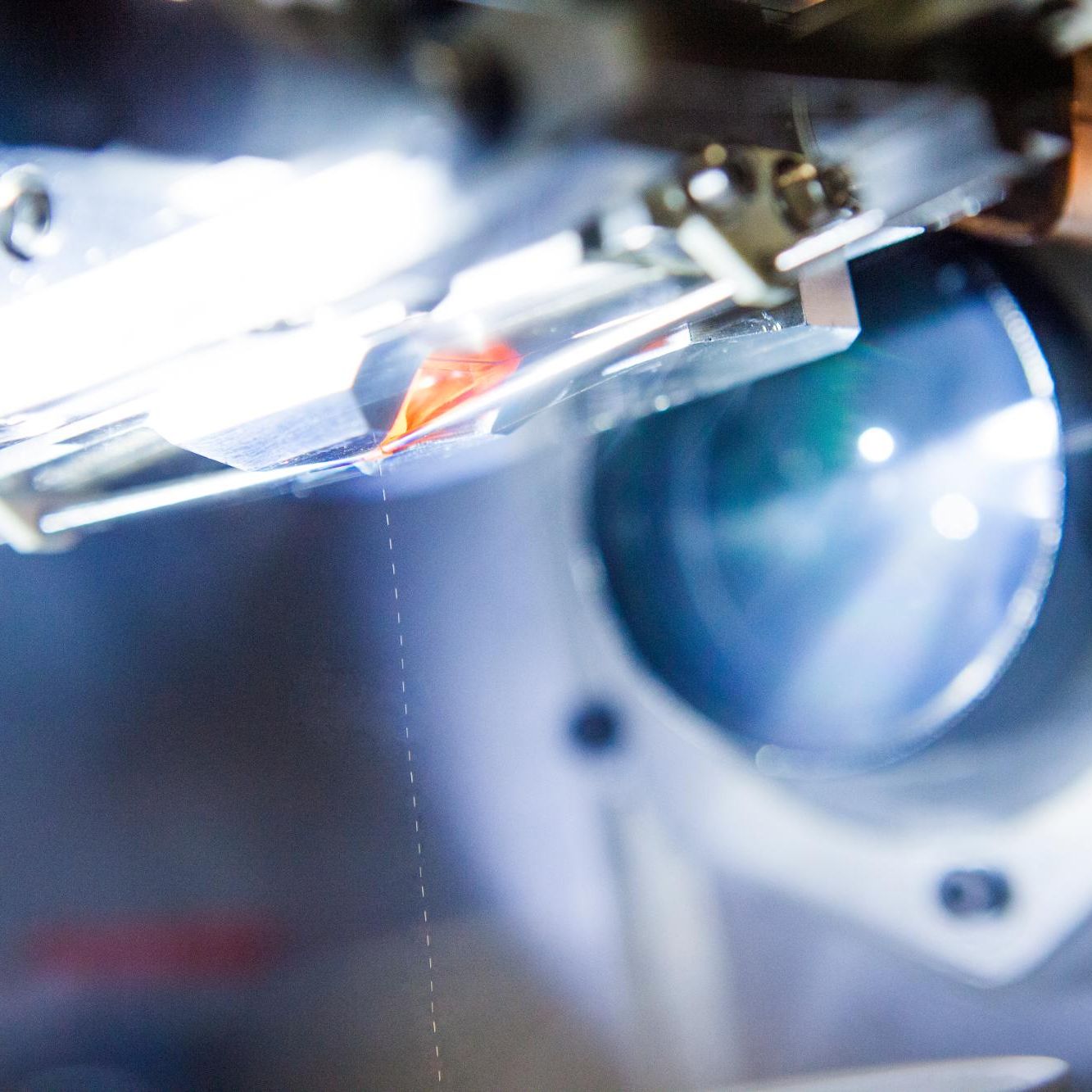

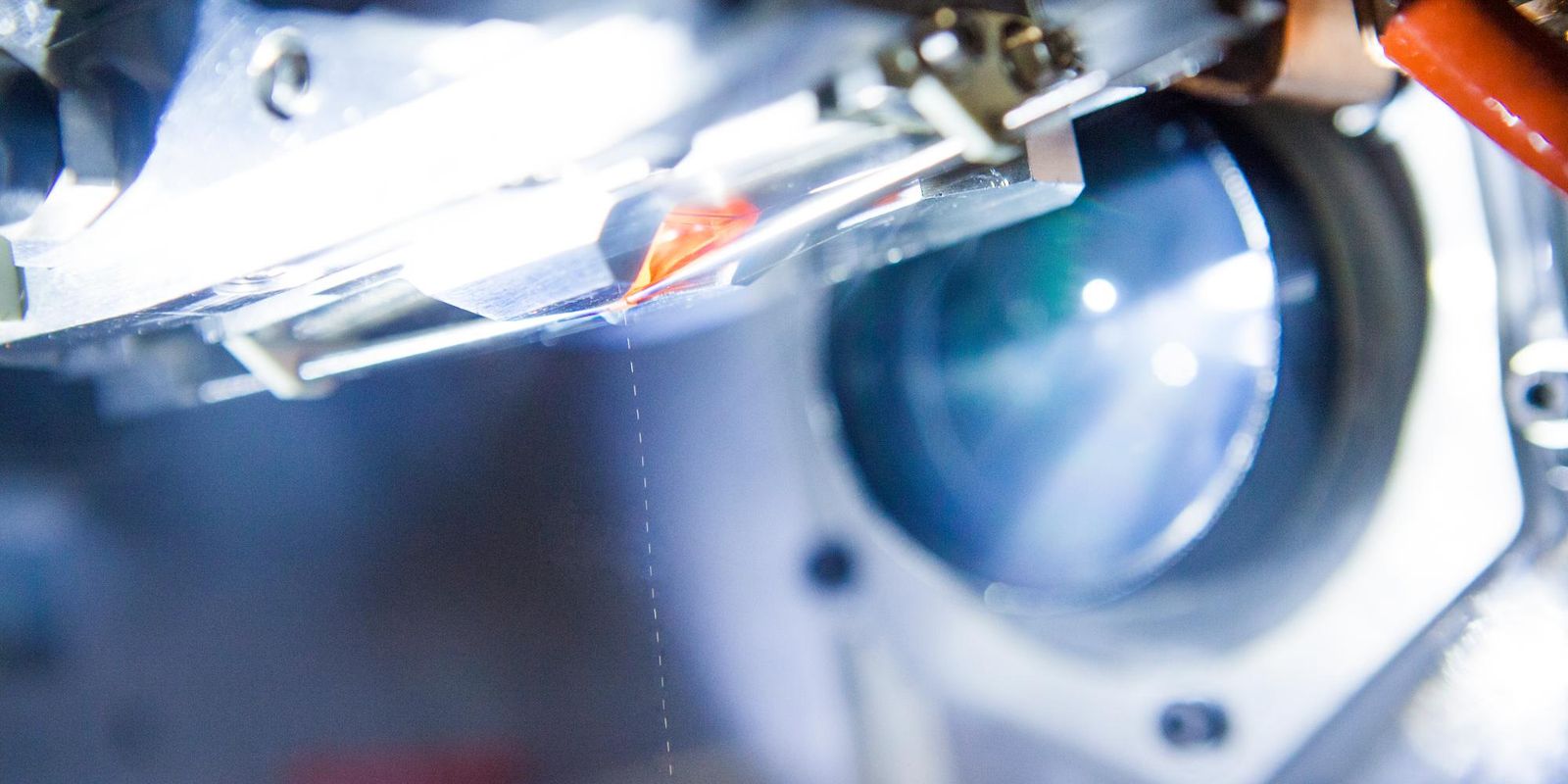

3D Metal Jet Printing is about printing products made from micrometer-range droplets of various metals. The high conductivity of copper and silver could be combined with the rigidity of aluminium or stainless steel. Demcon took on the challenge of enabling this process by meeting the daring printing conditions.

Read more

Hemics HandScan: fast, painless and objective screening for rheumatoid arthritis

There are not enough rheumatologists for frequent monitoring of all RA (Rheumatoid arthritis) patients. The Hemics HandScan device addresses this by using inflammation detection in the hands through optical spectral transmission (OST).

Read more

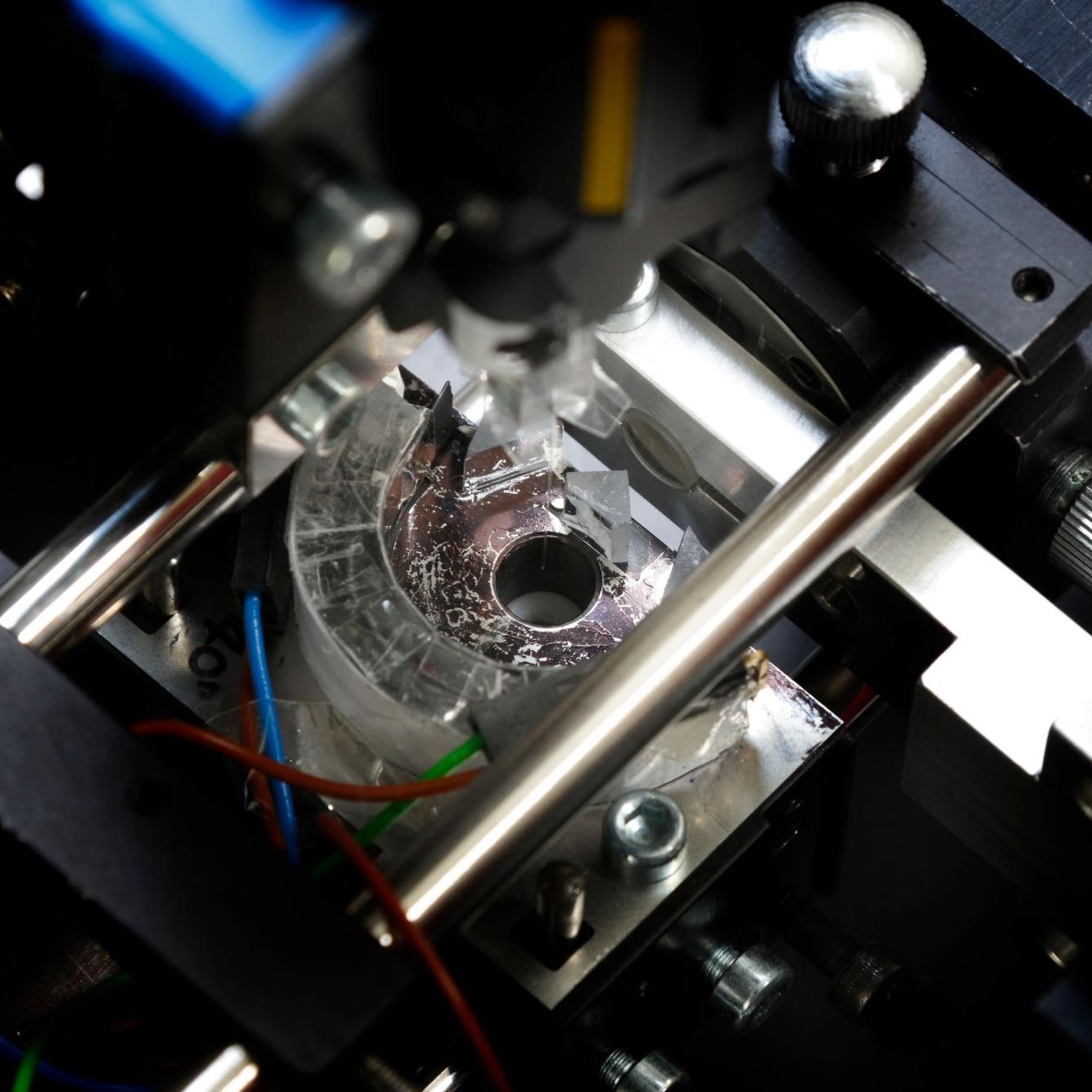

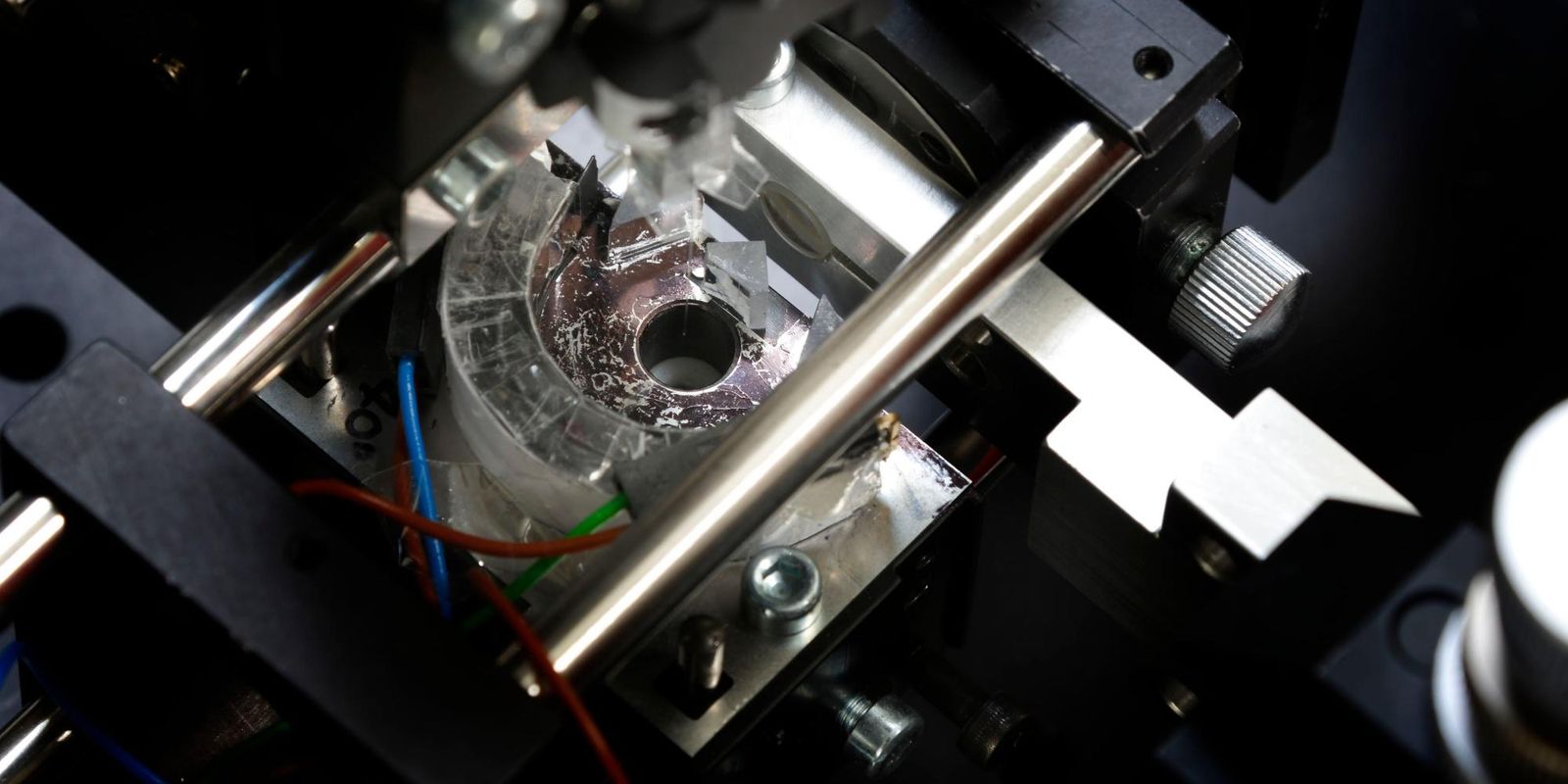

Glassfiber connection made easy

Lightning-fast internet via glass fiber – that’s what everyone wants. But one tricky point in roll-out is the manual connection of two fiber ends. That demands accuracy, takes time and requires skills. TE Connectivity developed a connector that lends itself to automatic processing by a so-called Light Plug Tool.

Read more

Short-stroke wafer stage

We designed a short-stroke wafer stage provided with a special metrology solution and high-efficiency motors. To this we added a complexly shaped magnetic shield, for which we developed a smart and dedicated manufacturing process.

Read more